VSW40 Wood Stove

60300060

9

INSTALLATION

WALL PASS-ThRUS

Whenever possible, design your installation so the

connector does not pass through a combustible wall. If

you must use a wall pass-through in your installation,

check with your building inspector before you begin and

construct it in accordance with local building codes. Also,

check with the chimney connector manufacturer for any

specific requirements.

Accessories are available from your dealer for use as wall

pass-throughs. If using one of these, make sure it has been

tested and listed for use as a wall pass-through.

All combustible material in the wall is cut away a sufficient

distance from the single-wall connector to provide the

required 12" (305 mm) clearance for the connector. Any

material used to close up the opening must be non-

combustible.

The following wall pass-through methods

may be

approved

in your area:

•

Use a section of listed factory-built chimney with a

nine-inch clearance to combustibles.

•

Place a chimney connector pipe inside a ventilated

thimble, which is then separated from combustibles

by 6" (152 mm) of fiberglass insulating material.

•

Place a chimney connector pipe inside a section

of listed solid-insulated, factory-built chimney,

with an inside diameter 1" (51 mm) larger than the

chimney connector and having 1" (25 mm) or more

of insulation and maintaining a minimum 2 inch air

space between the outer wall of the chimney and

combustibles.

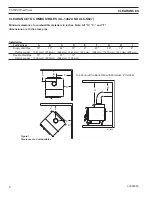

ST1009

wall pass thru

Chimney

Connector

12"

(305 mm)

12"

(305 mm)

ST1009

Figure 2 -

Wall Pass-thru Enclosed with

Noncombustible Materials

do not connect the heater to any air distribution duct

or system.

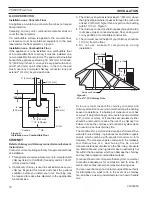

In Canada:

The Canadian Standards Association has

established different guidelines. Figure 11 shows one

method, in which all combustible material in the wall is cut

away to provide the required 18" (450 mm) clearance for

the connector. The resulting space must remain empty.

A flush mounted sheet metal cover may be used

on one

side only.

If covers must be used on both sides, each cover

must be mounted on non-combustible spacers at least 1"

(25 mm) clear of the wall. Your Vermont Castings dealer

or your local building inspector can provide details of other

approved methods of passing a chimney connector through

a combustible wall. In Canada, this type of installation must

conform to CAN/CSA-B365. Installation Code for Solid

Fuel Burning Appliances and Equipment.

NOTE:

Do not vent your stove into a factory-built (zero-

clearance) fireplace. These appliances and their chimneys

are specifically designed as a unit for use as fireplaces.

It may void the listing or be hazardous to adapt them for

any other use.

ST1010

hollow wall pass thru

Sheet Metal Cover

(This Side Only)

18" (450 mm)

Empty Space All Around the

Chimney Connector

ST1010

Figure 3 -

Hollow wall pass-thru