VSW40 Wood Stove

12

20300060

OPERATION & MAINTENANCE

BUILdING A FIRE

1. Open inlet air control fully.

2. Place a small amount of crumpled paper in the

stove.

3. Cover the paper with a generous amount of kindling

wood in a teepee fashion and a few small pieces of

wood.

4. Ignite the paper and close door. If fire dies down

substantially, open door slightly.

5. Add larger pieces of wood as the fire progresses being

careful not to overload. Do not fill firebox beyond

firebrick area. An ideal coal bed of 1" (25 mm) to 2"

(51 mm) should be established to achieve optimum

performance.

6. This unit is designed to function most effectively when

air is allowed to circulate to all areas of the firebox. An

ideal means of achieving this is to rake a slight (1" to

2" wide) trough in the center of the coal bed from front

to back prior to loading the fuel.

7. Once fuel has been loaded, close door and open air

inlet control fully until fire is well established (approx.

10 minutes) being careful not to over fire.

8. Re-adjust air inlet control to desired burn rate. If

excessive smoke fills firebox, open air inlet control

slightly until flames resume and wood is sufficiently

ignited. A basic rule of thumb is “closed – low,” "1/2

way-medium,” and “fully open – high.”

9. When refueling, adjust air control to the fully open

position. When fire brightens, slowly and carefully

open the door. This procedure will prevent gases from

igniting causing smoke and flame spillage.

10. Add fuel being careful not to overload.

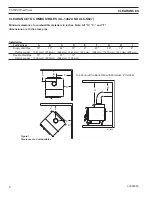

A

ST1013

air control

10/08

Low Burn

High Burn

Figure 6 -

Air Control Layout

ST1013

MAINTENANCE

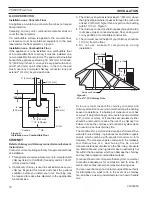

REMOVING FIREBRICk

To r e m o v e

firebrick, lift up

from bottom

a n d r o t a t e

o u t w a r d .

Figure 7

ST1018

remove firebrick

Firebrick

ST1018

Figure 7 -

Removing Firebrick

GLASS CARE

REPLACE GLASS ONLY WITh hIGh TEMPERATURE

CERAMIC AVAILABLE FROM YOUR LOCAL Vermont

Castings dEALER

The following use and safety tips should be observed:

1. Inspect the glass regularly for cracks and breaks. If you

detect a crack or break, extinguish the fire immediately,

and contact your dealer for replacement.

2. Do not slam door or otherwise impact the glass. When

closing doors, make sure that logs or other objects do

not protrude to impact the glass.

3. Do not clean the glass with materials which may scratch

(or otherwise damage) the glass. Scratches on the

glass can develop into cracks or breaks.

4. Never attempt to clean the glass while unit is hot. Light

deposits are normal. Heavier deposits may be removed

with the use of a readily available oven cleaner.

5. Never put substances which can ignite explosively in

the unit since even small explosions in confined areas

can blow out the glass.

6. This unit has an air wash system designed to reduce

deposits on glass.

GASkET REPLACEMENT

After extensive use, the sealing material which provides

glass and door seal may need to be replaced if it fails

to sustain its resilience. Inspect glass and door seal

periodically to ensure proper seal: if gaskets become

frayed or worn, replace immediately. Contact your Vermont

Castings dealer for approved replacement parts. Refer to

replacement parts list in this manual.

The following steps should be followed for glass gasket

replacement: