VSW40 Wood Stove

60300060

13

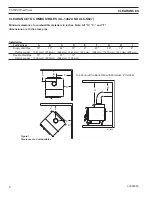

REMOVING ThE BAFFLE

To r e m o v e t h e

b a f f l e y o u w i l l

have to remove

the secondary air

tubes and the C-

cast baffle plates.

Figure 8

1. Use a Philips

head screw driv-

er or your fingers

to remove the

drywall screws

that are hanging

down next to the

secondary air tubes. These screws were for shipping

purposes only and can be discarded.

2. To remove the tubes, start by removing the cotter pin

on the left end of each tube, then slide the tube to the

right until the tube can be pulled down and left, and

removed from the stove. The four (4) lower tubes are

the same.

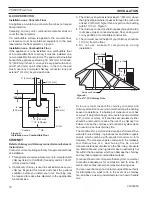

3. After all four tubes

have been removed

you can remove the

two piece C-cast baf-

fle.

Be very careful

not to damage the

baffle.

Carefully lift

up on the rear piece

and move it as far

back as possible let-

ting it sit on top of the

steel non-removable

baffle. Next, lift up on

the front piece and

move it to the left and

allow the right side to

angle down into the

firebox until it can be

removed through the

door opening. You can

now remove the rear

piece the same way.

Figures 9 and 10

6. Replace the C-cast baffle and tubes. After the tubes are

in place check to see that the c-cast baffle is slid back

against the steel non- removable baffle. Replace the

rear bricks.

1. Ensure appliance is not in operation and is thoroughly

cooled

2. Remove door and place on a protected flat surface.

3. Remove screws and glass clips.

4. Lift glass out.

5. Remove old gasket and clean glass.

6. Sand gasket groove and wipe clean (rubbing alcohol

works well).

7. Put a thin film of gasket cement on the door.

8. Replace new gasket starting at the top center of the

door.

9. Trim to length and butt ends together. Remove all

excess cement.

10. Replace glass in door, being sure not to over-tighten

screws and clips.

The following steps should be followed for door gasket and

ash pan door gasket replacement:

1. Ensure appliance is not in operation and is thoroughly

cooled.

2. Remove door and place on a protected flat surface.

3. Remove old door gasket and clean channel.

4. Sand gasket groove and wipe clean (rubbing alcohol

works well).

5. Using an approved high temperature gasket cement,

apply a thin coat in bottom of channel.

6. Starting at top center of door, work into channel around

door unit, trim to length and butt ends.

7. Close door and allow three to four hours for cement to

set before restarting appliance.

MAINTENANCE

Secondary Air

Tubes

C-Cast Baffle

ST1014

secondary air tubes

Figure 8

ST1014

ST1015

baffle

ST1015

ST1016

remove baffle

ST1016

Figure 10

Figure 9