Fume Exhaust Fans

15

Wheel and Fastener Maintenance

Wheels require very little attention when exhausting

clean air, however, air heavily laden with grease or

dirt will tend to accumulate on the wheel causing

unbalance. Wheels exhausting dirty or grease-laden air

require frequent cleaning to assure smooth and safe

operation.

All fasteners, including set screws in the bearing collars,

should be checked for tightness each time maintenance

checks are performed.

A proper maintenance program will help preserve the

performance and reliability designed into the fan.

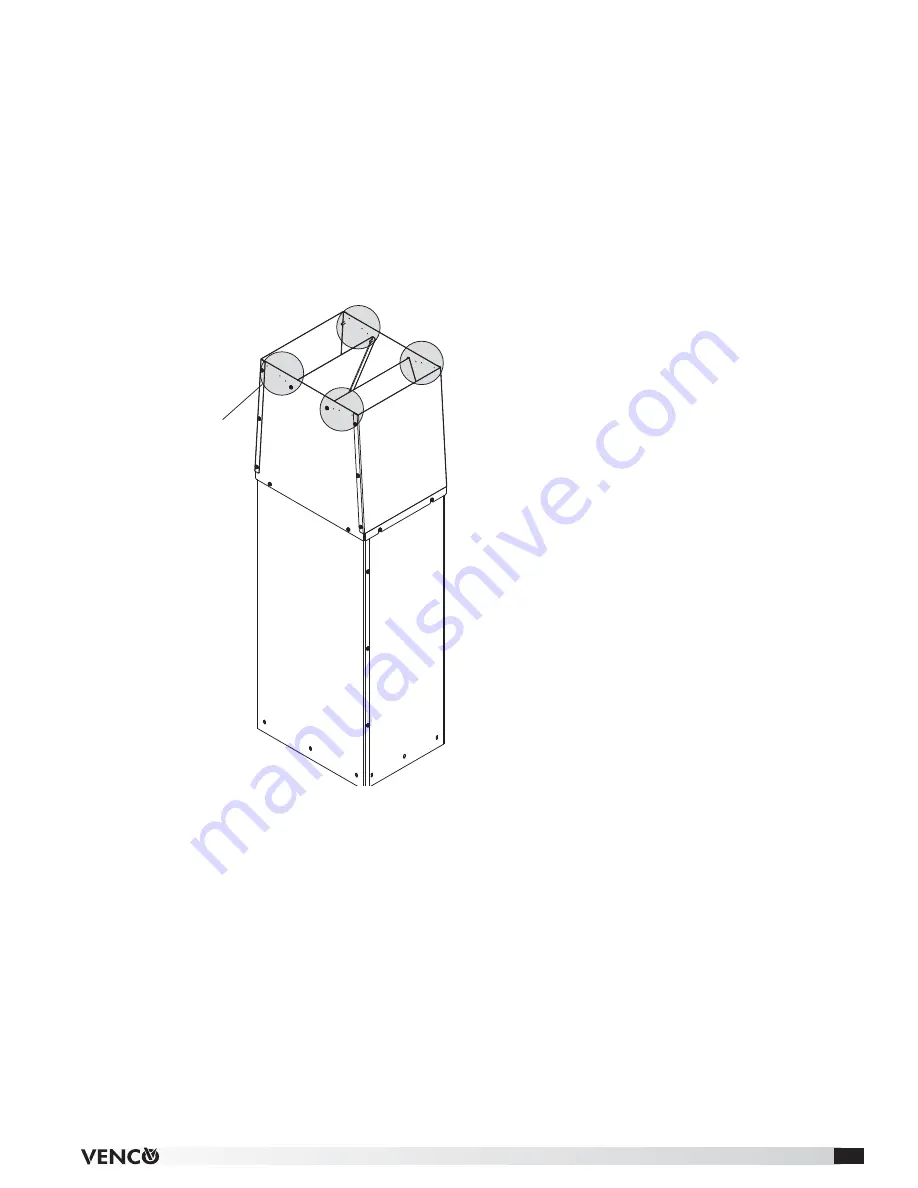

Field Adjustable Nozzle

When ordered with an adjustable nozzle, the fume

exhaust system will arrive at the job site with the nozzle

preset at the factory based on the order. Depending on

installed air performance, this nozzle can be adjusted in

the field to accommodate the building situation.

To increase the exhaust velocity and plume height,

close the adjustable nozzle when possible. Verify the

fan speed and motor horsepower to ensure system can

manage the increased pressure the fan must overcome

To lower velocity and decrease plume height, open the

adjustable nozzle.

To modify the area on the field adjustable nozzle,

remove the bolts from each side and move the plate to

the desired position. Bolts are to be located in the same

hole on each side of the plate, but each plate can be

adjusted independently. Replace the bolt and tighten.

After any change, verify the system exhaust for proper

amount of air volume being exhausted.

Pre-drilled adjustment holes

available for increasing or

decreasing outlet area.