6. Cleaning

ROBOT HP7C / HP10C / HP15C / HP17C

6-10

© VEMAG 2004

6.3 Cleaning the machine

Clean the machine housing, the hopper, the feed screw, the linking gear

(optional) and all the parts which have been removed thoroughly with hot

water and a brush and then dry them. The machine is suitable for cleaning

with low-pressure cleaning equipment (max. 25 bar).

Warning!

Never aim the jet of water directly at the double screw drive, the sealing

elements and the machine control panel when using low-pressure

cleaning equipment and keep the nozzle at the distance from the surface

of the machine specified for the cleaning equipment.

In addition to the instructions in the cleaning schedule, generally-

applicable and product-specific hygiene regulations should be followed.

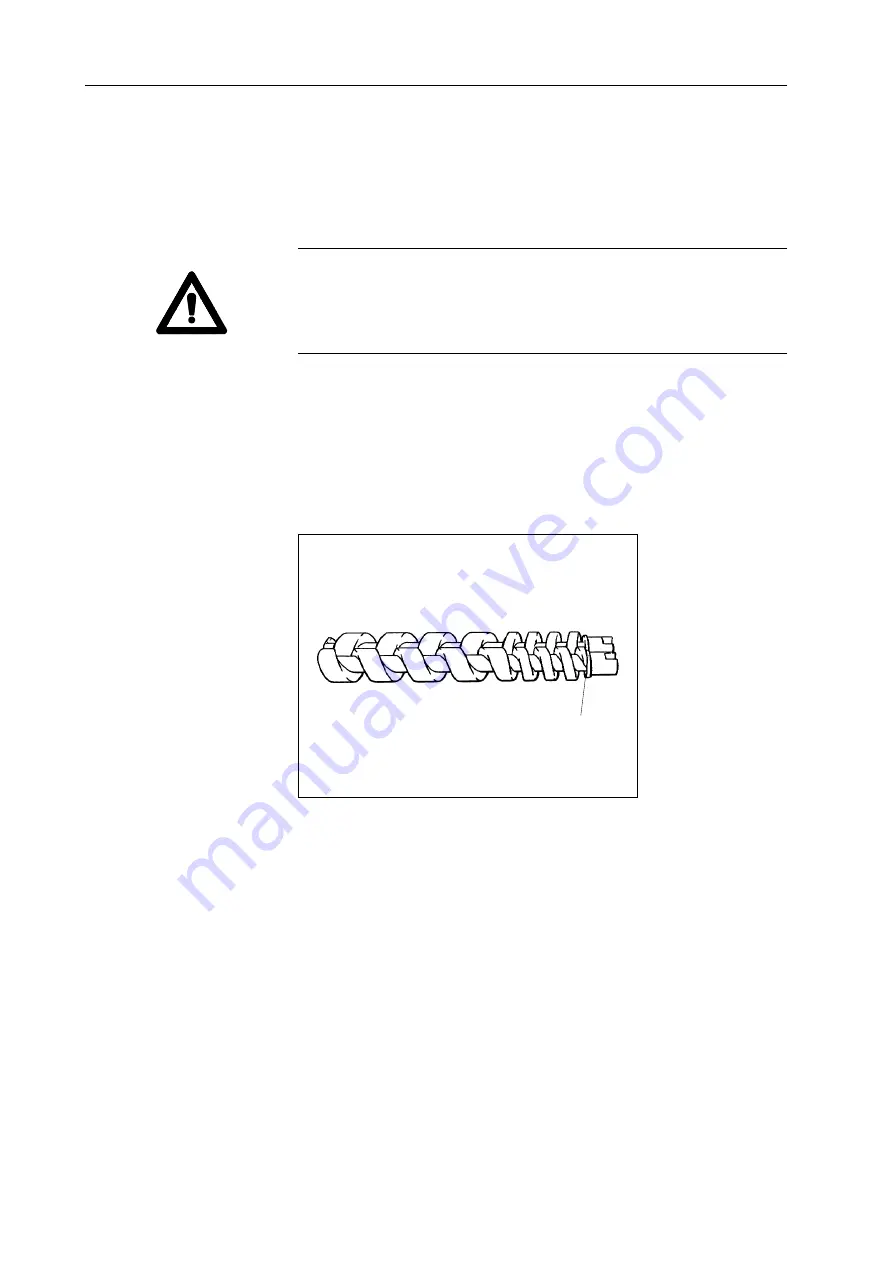

When cleaning the double screws, pay particular attention to the joints

between the screw and the coupling claw (1).

1

1

Joint

Fig. 6-16

Double screws

Summary of Contents for ROBOT HP7C

Page 6: ...Index iv VEMAG 2004 ROBOT HP7C HP10C HP15C HP17C...

Page 8: ...0 Foreword 0 2 VEMAG 2004 ROBOT HP7C HP10C HP15C HP17C...

Page 20: ...2 Description ROBOT HP7C HP10C HP15C HP17C 2 8 VEMAG 2004...

Page 30: ...3 Installation and commissioning ROBOT HP7C HP10C HP15C HP17C 3 10 VEMAG 2004...

Page 82: ...8 Troubleshooting 8 4 ROBOT HP7C HP10C HP15C HP17C VEMAG 2004...