12

106309-03 - 4/19

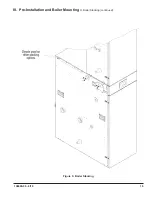

III. Pre-Installation and Boiler Mounting

G. General (continued)

WARNING

Asphyxiation Hazard. Adequate combustion and

ventilation air must be provided to assure proper

combustion. Install combustion air intake per

Section IV “Venting”.

F. The boiler should be located

so as to minimize

the length of the vent system. Locate combustion air

pipe termination away from areas that may contaminate

combustion air, (see Table 4). In particular, avoid

areas near chemical products containing chlorines,

chlorofluorocarbons, paint removers, cleaning solvents

and detergents. Avoid areas containing saw dust, loose

insulation fibers, dry wall dust etc.

NOTICE

Avoid operating this boiler in an environment

where sawdust, loose insulation fibers, dry wall

dust, etc. are present. If boiler is operated under

these conditions, the burner interior and ports

must be cleaned and inspected daily to insure

proper operation.

G. General.

1. Phantom X boilers are intended for installations in

an area with a floor drain, or in a suitable drain pan

to prevent any leaks or safety relief valve discharge

resulting in property damage.

2. Phantom X boilers are not intended to support

external piping and venting. All external piping and

venting must be supported independently of the

boiler.

3. Phantom X boilers must be installed level to prevent

condensate from backing up inside the boiler.

4. Boiler Installation:

a. For basement installation provide a solid level

base such as concrete where floor is not level or

where water may be encountered on the floor

around boiler. Floor must be able to support

Table 5: Vent Pipe Clearances to Combustible Material

Boiler Clearances to Combustible (and Non-

Combustible) Material:

Models PHNTM399C and PHNTM500C:

These boilers are listed for closet installation with the

following minimum clearances – Top = 1 in. (25 mm),

Front = 1 in. (25 mm), Left Side = 10 in. (250 mm),

Right Side = 2 in. (50 mm), Rear = *6 in. (150 mm)

Models PHNTM600C, PHNTM700C and

PHNTM800C:

These boilers are listed for alcove installation with the

following minimum clearances – Top = 1 in. (25 mm),

Front = Open, Left Side = 10 in. (250 mm), Right Side

= 2 in. (50 mm), Rear = *6 in. (150 mm)

* Note:

When boiler is vented vertically, the minimum

clearance from the rear of the jacket is increased to

18 in. (460 mm) with a short radius 90° elbow

provided in order to provide adequate space at boiler

rear for installation of vent and air intake piping and

service access.

Boiler Service Clearances – Applicable to all Boiler

Models:

Top = 24 in. (610 mm), Front = 24 in. (610 mm), Left

Side = 24 in. (610 mm), Right Side = 24 in. (610 mm),

Rear = 24 in. (610 mm)

The above clearances are recommended for service

access but may be reduced to the Combustible Material

Clearances provided:

1. The boiler front is accessible through a door.

2. Access is provided to the condensate trap located on

the left side of boiler.

3. Access is provided to thermal link located at the

boiler rear.

Listed Direct

Vent System

Vent Pipe Material

Vent Pipe

Direction

Enclosure

Vent Pipe

Nominal Diameter

Minimum

Clearance to

Combustible

Material

Standard

Two-Pipe CPVC/PVC Vent and PVC Combustion Air Intake

CPVC/PVC

Vertical or

Horizontal

Unenclosed

at all Sides

3 in. (80 mm),

4 in. (100 mm or 110 mm)

6 in. (150 mm or 160 mm)

1 in. (25 mm)

Optional

Two-Pipe Rigid Polypropylene Vent (or, Flexible Polypropylene

Liner for Vertical Venting only) and Rigid Polypropylene or PVC

Combustion Air Intake

Rigid Polypropylene (or,

Flexible Polypropylene

Liner for Vertical Venting

only)

3 in. (80 mm),

4 in. (100 mm or 110 mm)

6 in. (150 mm or 160 mm)

1 in. (25 mm)

Optional

Two-Pipe Stainless Steel Vent and Galvanized Steel or PVC

Combustion Air Intake

Stainless Steel

3 in. (80 mm),

4 in. (100 mm or 110 mm)

6 in. (150 mm or 160 mm)

1 in. (25 mm)

weight of boiler, water and all additional system

components.

b. Boiler must be level to prevent condensate from

backing up inside the boiler.

c. Provide adequate space for condensate piping or

a condensate pump if required.

Summary of Contents for Phantom-X Series

Page 49: ...49 106309 03 4 19 VI Water Piping and Trim continued Figure 28 Near Boiler Piping Heating Only...

Page 63: ...63 106309 03 4 19 VIII Electrical continued Figure 40 Ladder Diagram...

Page 64: ...64 106309 03 4 19 VIII Electrical continued Figure 41 Wiring Connections Diagram 2...

Page 73: ...73 106309 03 4 19 IX System Start up continued Figure 47 Operating Instructions...

Page 124: ...124 106309 03 4 19 XIII Service Parts continued...

Page 130: ...130 106309 03 4 19 XIII Service Parts continued...

Page 133: ...133 106309 03 4 19 XIII Service Parts continued 10A 10B 10C 10D 10G...

Page 139: ...139 106309 03 4 19...