34

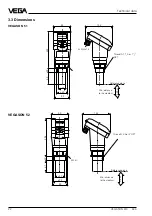

VEGASON 51K … 53K

Wrong

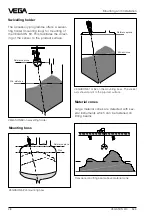

Mounting on a vessel with parabolic tank top

Correct

~

1

/

2

vessel

radius

Wrong

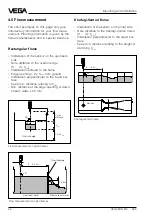

Max. meas.

distance

Distance of the

transducer to the

vessel wall

Curve 1 (liquids)

Curve 2 (solids)

Mounting and installation

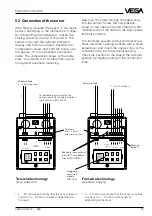

Sensor too close to the vessel wall

if the sensor is mounted too close to the ves-

sel wall (dimension A in diagram) strong false

echoes can be caused. Build-up, rivets,

screws and weld joints superimpose their

echoes on the product echo or useful echo.

Please ensure the sufficient distance of the

sensor to the vessel wall depending on the

maximum measuring distance (dimension B

in diagram). In case of good reflection condi-

tions (liquids, no vessel installation) we rec-

ommend the provision of the sensor distance

according to

diagram curve 1

. At a max.

meas. distance of, for example 10 m the

distance of the transducer, according to

curve 1, should be approx. 1 m. In case of

solids with bad reflection conditions provide

a distance to the vessel wall according to

diagram curve 2

. With very bad meas. con-

ditions it could be necessary to increase the

distance to the vessel wall or to gate out the

false echoes additionally by a false echo

storage and thereby adapt the sensor more

precisely to the environment.

Parabolic effects on dished boiler head

or basket arch vessels

Round or parabolic tank tops act like a para-

bolic mirror for the signals. If the sensor is

placed to the focus of such a parabolic tank

top the sensor receives amplified false ech-

oes. The optimum mounting is generally in the

range of half the vessel radius from the cen-

tre.

³

60 mm