6

3

5

4

1

2

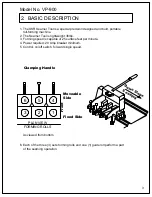

Clamping Handle

PLAN VIEW

FORMING ROLLS

As viewed from bottom

Moveable

Fixed Side

F

ro

n

t

Side

FIG. 1

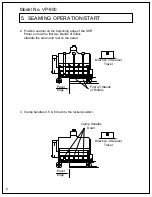

FIG. 2

FIG. 3

4

1

5

2

6

3

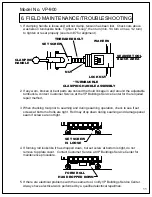

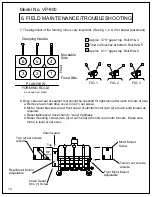

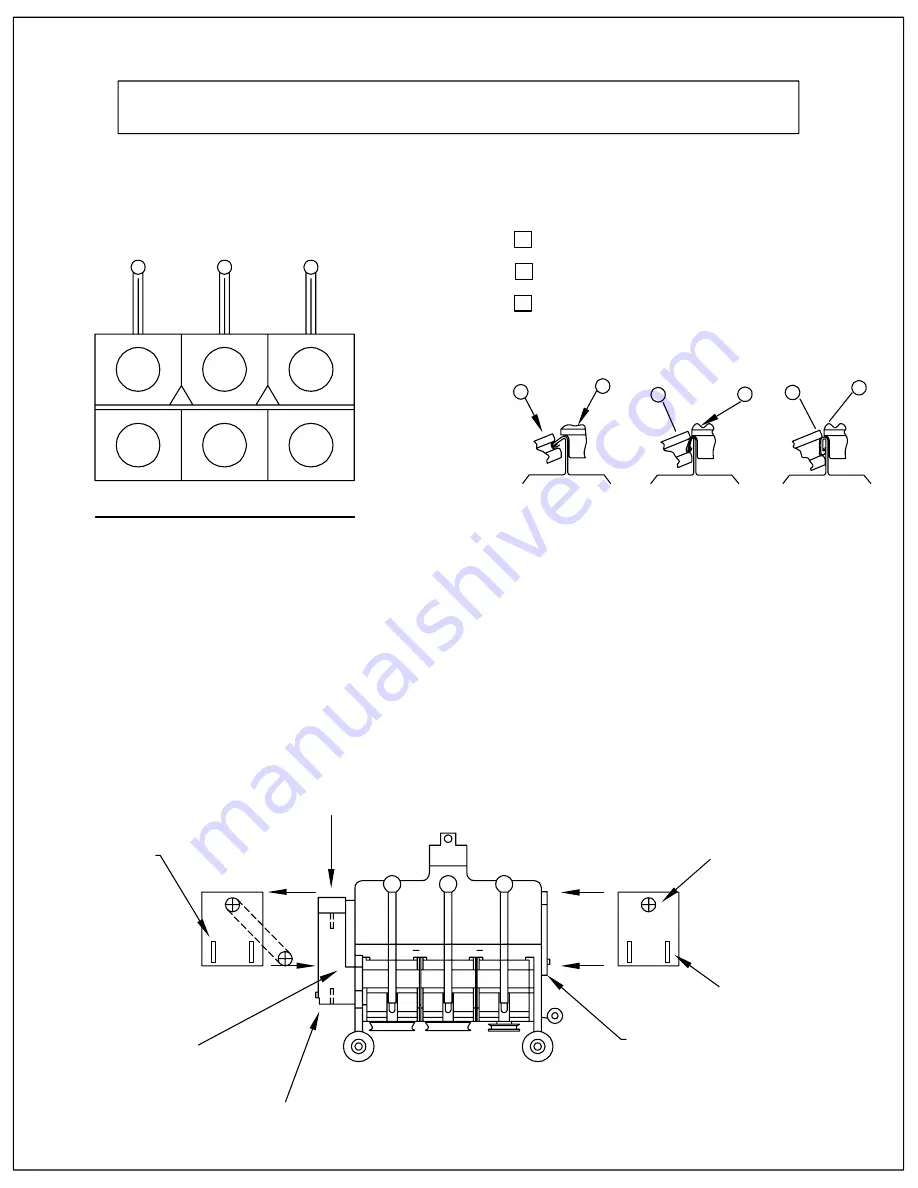

7. The alignment of the forming rolls is very important. (See fig. 1, 2 & 3 for proper placement)

Approx. 0.75" gap at top. Roll #1 & 4

Fiber roll touches at bottom. Roll #2 & 5

Approx. 0.11" gap at top. Roll #3 & 6.

1

3

2

8. Drive chain at rear of seamer tool should be checked for tightness (after each 8 hours of use).

a. Remove rear chain drive cover (one (1) set screw).

b. Motor mount brackets are at front & rear of electric motor (two (2) at each end) loosen as

required.

c. Reset tightness of drive chain to "snug" tightness.

d. Reset mounting screws (two (2) at each end) at front & rear motor mounts. Make sure

motor is level or set even.

Front Motor Mount

Adjustable

Motor Mount

Screw

Two (2) set screws

w/slots

Chain Guard

Chain Guard

One (1) Screw

Rear Motor Mount

Adjustable

Two (2) set screws

w/slots

Top

Bottom

Drive

Sprocket

Model No. VP-900

12

6. FIELD MAINTENANCE/TROUBLESHOOTING

Summary of Contents for SSR 900

Page 2: ......

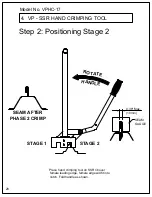

Page 20: ...Model No VPHC 17 17 1 VP SSR HAND CRIMPING TOOL...