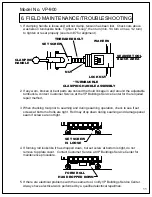

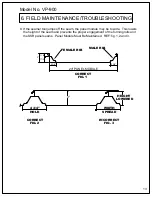

THREADED BOLT

SET SCREW

WAHERS

NUT

LOCK NUT

SEAMER TOOL

CLAMPING

BLOCK AREA

HANDLE

1. If clamping handle is loose and will not clamp, tension has been lost. Check nuts above

washers on turnbuckle bolts. Tighten to "snug", then turn (min. 1/4 turn or max, 1/2 turn)

to tighten or reset properly (see item #7 for alignment).

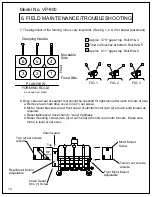

2. If any worn, broken or bent parts are noticed that hold linkage in and around the adjustable

turnbuckle, contact Customer Service at the VP Buildings Service Center for the rerquired

repair method.

3. When checking tool prior to seaming and during seaming operation, check to see if set

screws at bottom of rolls are tight. Roll may drop down during seaming and damage panel

seam if screws are not tight.

4. If forming roll looks like it has dropped down, but set screw at bottom is tight, do not

remove top plate cover. Contact Customer Service at VP Buildings Service Center for

maintenence procedure.

5. If there are electrical problems with the seamer tool, notify VP Buildings Service Center.

Always have electrical work performed by a qualified electrical repairman.

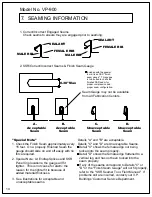

SET SCREW

IS LOOSE

FORM ROLL

HAS DROPPED DOWN

Model No. VP-900

*TURNBUCKLE

CLAMPING HANDLE ASSEMBLY

11

6. FIELD MAINTENANCE/TROUBLESHOOTING

Summary of Contents for SSR 900

Page 2: ......

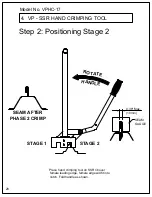

Page 20: ...Model No VPHC 17 17 1 VP SSR HAND CRIMPING TOOL...