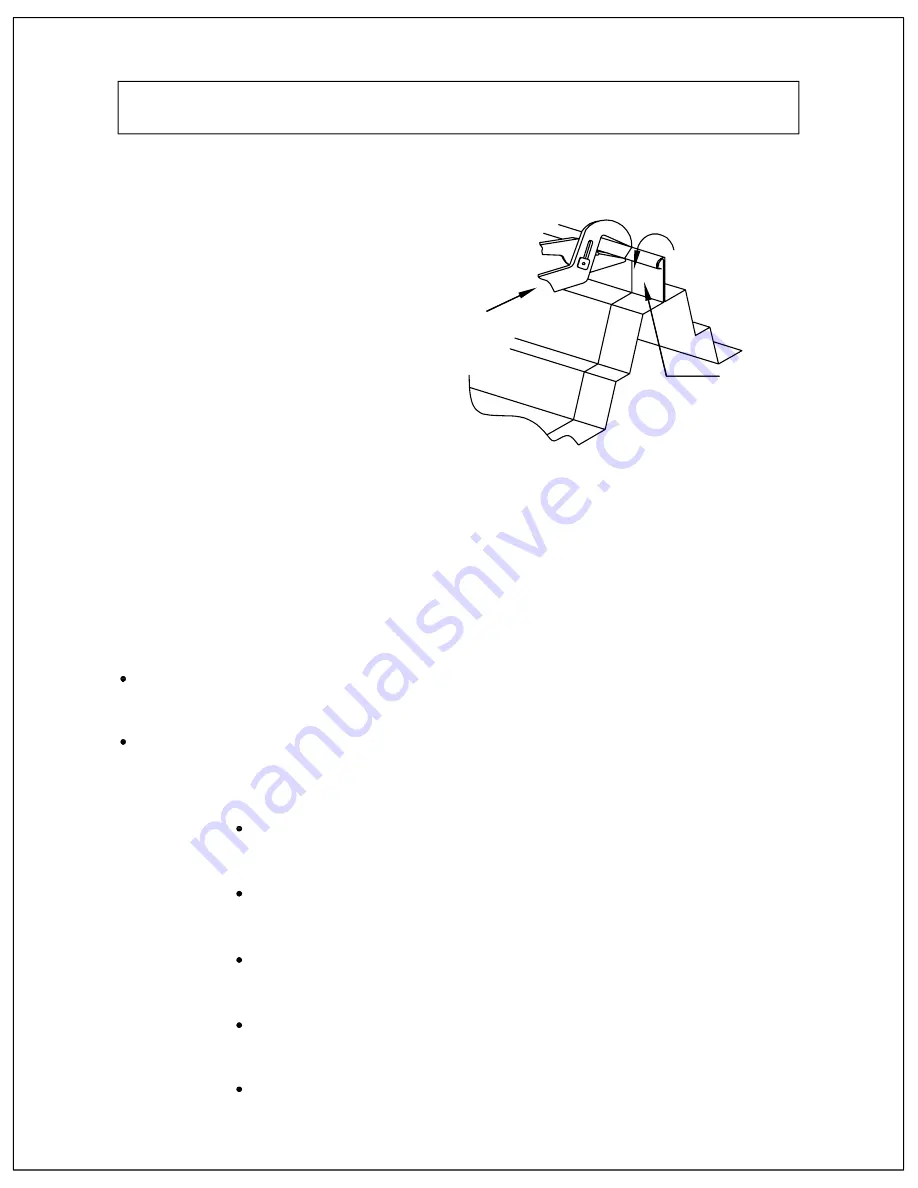

TUCK LIP

CHANNEL LOCKS

NOTE:

End Lap

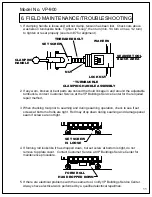

A. When the seamer tool approaches

the End Lap, the seamer

tool before crossing the End Lap

and hand crimp the leading edge

of female lip. Also, it will slow

down due to the additional

thickness of metal. This heavier

load requirement can be

detrimental to the seamer tool

if it should come to a complete

stall. The operator should assist by

manually pushing the seamer forward

by the handle until the seamer clears

the lap.

B. Hand crimping at

"Crimping the female lip of seam into position."

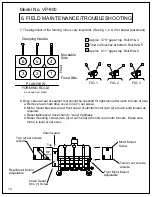

NOTE: Starting Seamer Tool at MIDPOINT OF SEAM.

It is possible to start Seamer Tool Model No. VP-900 in the

middle of a seam run; however,it is not recommended.

If required: page 12-item 8-Guide Roll and forming rolls,

figures 1,2,3 and 4.

page 7 and 8 -seaming Operation/Start

Engage rollers, #1 and #4, clamp handle #1 down, advance

seamer tool approx. 2"

Engage rollers, #2 and #5, clamp handle #2 down, advance

seamer tool approx. 2"

Engage rollers, #3 and #6, clamp handle #3 down, advance

seamer tool approx. 2"

seamer tool and check rollers and seams to make sure

they are engaged properly!

Start seamer tool and continue the seaming operation.

items 2,3,4 and 5.

Model No. VP-900

STOP

REVIEW

REVIEW

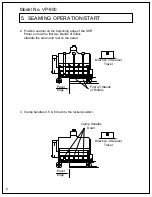

Start of Seaming Operation.

"STOP"

10

5. SEAMING OPERATION/START

Summary of Contents for SSR 900

Page 2: ......

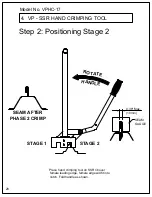

Page 20: ...Model No VPHC 17 17 1 VP SSR HAND CRIMPING TOOL...