Page 14

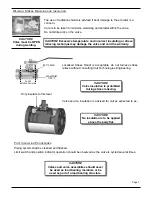

Pressure Seal Standoff

14) Place body with end cap end up. Carefully align pressure seal parallel with body face. Very

carefully place the end cap atop the body and pressure seal. All must be horizontal.

15) Check the body gap (pressure seal standoff). See Table 4. If the gap is out of tolerance, an over-

sized body may be used.

Pressure Seal

Stand-Off

Body Seal

End-Cap

Body

NOMINAL BALL BORE

(I.D.) – in. (mm)

STAND OFF – in. (mm)

MINIMUM

MAXIMUM

5/8 (16)

.023 (.584) .041

(1.0414)

1-1/16 (27)

.041 (1.0414)

.068 (1.727)

1-1/2 (38)

.045 (1.143)

.068 (1.727)

2-1/8 (54)

.048 (1.219)

.071 (1.803)

3-1/16 (78)

.078(1.981)

.105 (2.667)

4-1/16 (103)

.095 (2.413)

.125 (3.175)

5-1/8 (130)

.120 (3.048)

.145 (3.683)

6-1/16 (154)

.145 (3.683)

.178 (4.521)

8-1/16 (205)

.180 (4.572)

.210 (5.334)

10-1/16 (256)

.230 (5.842)

.260 (6.604)

12-1/8 (308)

.275 (6.985)

.310 (7.874)

15-1/4 (387)

.305 (7.747)

.345 (8.763)

17-1/4 (438)

.330 (8.382)

.370 (9.398)

19-1/4 (489)

.350 (8.89)

.390 (9.906)

21-1/4 (540)

.380 (9.652) .430

(10.922)

TABLE 4

ASSEMBLY STAND OFF OF PRESSURE SEAL (without ball)

(PRESSURE SEAL VALVES ONLY

)

Note: If standards are not in this range, then ValvTechnologies Engineering approval is required prior to as-

sembly.

NOTE:

This measurement is only required on valves with a metal body seal.