Page 18

TESTING

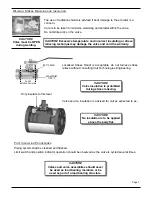

1) Valves may be tested in accordance with ValvTechnologies’ Quality Procedure, VQP 010.

2) When performing the seat test, the pressure must be applied on the upstream side. The arrow on

the valve (or the label indicating the high pressure end) will indicate the direction in which pressure

should be applied.

NOTE:

Bi-directional valves must be tested with consideration for the required reverse

pressure sealing. Prior to any testing of bi-directional valves, a ValvTechnologies approved

service center should be consulted to gain the correct test procedure and test pressure.

MALFUNCTION

POSSIBLE CAUSE

REMEDIAL ACTION

Valve will not rotate or

operate

1) Actuator has failed

2) Valve packed with debris

3) Stem key has sheared

4) Ball seat gap incorrect

1) Replace or repair actuator

2) Cycle & flush valve to re-

move debris

3) Determine cause of shear-

ing & correct/replace keys

4) Call

Factory

Stem Packing Leaking

1) Gland bolts loose

2) Packing damaged or missing

3) Seal

misaligned

1) Tighten gland bolts

2) Shut down system & re-

place packing

3) Replace & properly align

Body Gasket Leaking

1) Body Bolts loose

2) Body gasket damaged

3) Body gasket seating faces in

body or end piece damaged

1) Tighten body bolts

2) Remove valve from service

& replace body gasket

3) Return parts to ValvTech-

nologies for rework

Valve Ball/Seat Leaking

1) Valve not fully closed

2) Debris trapped in valve

3) Seat or ball damaged

1) Close the valve

2) Cycle & flush to remove

debris.

TROUBLE SHOOTING