8 Adapting the unit to the heating installation

26

Installation and maintenance instructions ecoTEC plus 0020261188_00

8

Adapting the unit to the heating

installation

To reset the most important system parameters, call up the

Appliance config.

menu item.

Menu

→

Installer level

→

Appliance config.

Or manually relaunch the installation assistant.

Menu

→

Installer level

→

Start inst. assistant

8.1

Activating diagnostics codes

The setting options for more complex installations can be

found in the diagnostics codes.

Menu

→

Installer level

→

Diagnostics menu

You can use the parameters that are marked as adjustable

in the overview of diagnostics codes to adapt the product to

the heating installation and the needs of the customer.

▶

Press

or

to change the diagnostics code.

▶

Press

(

Select

) to select the parameter to change.

▶

Press

or

to change the current setting.

▶

Confirm by pressing (

OK

).

8.2

Adapting the heating settings

8.2.1

Setting the maximum heating output

The maximum heating output for the product is set to

Auto

at the factory. If you want to set a fixed maximum heat out-

put, you can use diagnostics code

D.000

to define a value

that corresponds to the product output in kW.

8.2.2

Setting the burner anti-cycling time

To prevent frequent switching on and off of the burner and

thus prevent energy losses, an electronic restart lockout

is activated for a specific period each time the burner is

switched off. You can adjust the burner anti-cycling time to

the conditions of the heating installation. The burner anti-

cycling time is only active for the heating mode. Switching on

domestic hot water mode during the burner anti-cycling time

has no effect. You can use diagnostics code

D.002

to set the

maximum burner anti-cycling time (factory setting: 20 min.).

The effective burner anti-cycling times with respect to the

target flow temperature and the maximum set burner anti-

cycling time can be found in the following table:

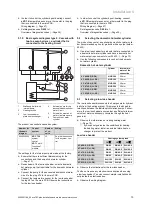

T

Flow

(target)

℃

Set maximum burner anti-cycling time

min

1

5

10

15

20

25

30

30

2.0

4.0

8.5

12.5

16.5

20.5

25.0

35

2.0

4.0

7.5

11.0

15.0

18.5

22.0

40

2.0

3.5

6.5

10.0

13.0

16.5

19.5

45

2.0

3.0

6.0

8.5

11.5

14.0

17.0

50

2.0

3.0

5.0

7.5

9.5

12.0

14.0

55

2.0

2.5

4.5

6.0

8.0

10.0

11.5

60

2.0

2.0

3.5

5.0

6.0

7.5

9.0

65

2.0

1.5

2.5

3.5

4.5

5.5

6.5

70

2.0

1.5

2.0

2.5

2.5

3.0

3.5

75

2.0

1.0

1.0

1.0

1.0

1.0

1.0

T

Flow

(target)

℃

Set maximum burner anti-cycling time

min

35

40

45

50

55

60

30

29.0

33.0

37.0

41.0

45.0

49.5

35

25.5

29.5

33.0

36.5

40.5

44.0

40

22.5

26.0

29.0

32.0

35.5

38.5

45

19.5

22.5

25.0

27.5

30.5

33.0

50

16.5

18.5

21.0

23.5

25.5

28.0

55

13.5

15.0

17.0

19.0

20.5

22.5

60

10.5

11.5

13.0

14.5

15.5

17.0

65

7.0

8.0

9.0

10.0

11.0

11.5

70

4.0

4.5

5.0

5.5

6.0

6.5

75

1.0

1.0

1.0

1.0

1.0

1.0

Note

The remaining burner anti-cycling time following a

regular shutdown in heating mode can be called

up under diagnostics code

D.067

.

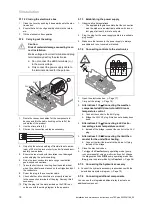

8.2.3

Resetting the remaining burner anti-cycling

time

1st option

Menu

→

Reset anti-cycl. time

The current burner anti-cycling time appears in the display.

▶

Confirm the burner anti-cycling time reset by pressing

(

Select

).

2nd option

▶

Press the reset button.

8.2.4

Setting the pump overrun and pump mode

You can set the pump overrun under

D.001

(factory setting:

5 min.).

You can use diagnostics code

D.018

to set the pump mode

Comfort

or

Eco

.

In the

Comfort

operating mode, the internal pump is

switched on when the heating flow temperature is not at

Heating off

(

→

Operating instructions) and the heat demand

is enabled via an external control.

The

Eco

operating mode (factory setting) is useful for re-

moving residual heat after hot water generation when the

heat demand is extremely low and large target temperature

spreads exist between the hot water generation and heat-

ing mode target values. This prevents living rooms from be-

ing under-supplied. If there is a heat demand, the pump is

switched on every 25 minutes for 5 minutes once the overrun

time has elapsed.