Start-up 7

0020261188_00 ecoTEC plus Installation and maintenance instructions

23

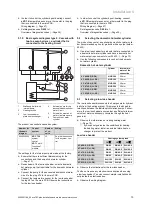

Display

Meaning

P.00

Purging check programme:

The internal pump is cyclically actuated.

The heating circuit and the domestic hot water circuit

are purged via the air separation system.

1 x

: Start the heating circuit purging

2 x

(

→

): Start the domestic hot water circuit

purging

3 x

(

→

): Restart the heating circuit purging

1 x

(

Cancel

): End the purge programme

Note

The purging programme runs for 6.5 minutes per

circuit and then terminates.

P.01

Maximum load check programme:

After successful ignition, the product is operated at

maximum heat input if the flow rate in the heating

circuit permits this. Otherwise, the power is reduced

in order to adapt to the flow rate.

P.02

Minimum load check programme:

After successful ignition, the product is operated at

minimum heat input if the flow rate in the heating

circuit permits this. Otherwise, the product does not

ignite and it remains in waiting mode (status code

S.85

).

Note

If the product is in error condition, you cannot start

any check programmes. You can detect an error

condition by the fault symbol shown in the left

bottom corner of the display. You must first reset.

To terminate the check programmes, you can select (

Can-

cel

) at any time; this does not apply for initial start-up, how-

ever. The purging cycle must be completely carried out once

so that the burner can ignite.

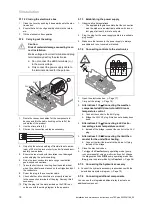

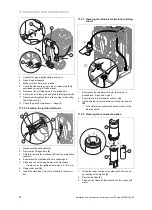

7.8

Check and gas setting

7.8.1

Checking the factory setting

Caution.

An incorrect gas type setting may cause

malfunctions or a reduction in the service

life of the product.

If the product design does not match the local

gas type, this may lead to malfunctions or to

some components wearing prematurely.

▶

Before you start up the product, compare

the gas type information on the data plate

with the gas type group available at the

installation site.

The product's combustion has been factory tested and is

preset for operation with the gas type indicated on the data

plate. In some supply areas, these settings may need to be

adjusted at the installation site.

Conditions

: The product design is not compatible with the local gas type

▶

Do not start up the product.

▶

Carry out a gas conversion in accordance with your in-

stallation.

Conditions

: The product design is compatible with the local gas type

▶

Proceed as described below.

7.8.2

Checking the gas flow pressure

Caution.

Risk of material damage and operating

faults caused by incorrect gas flow pres-

sure.

If the gas flow pressure lies outside the per-

missible range, this can cause operating

faults in and damage to the product.

▶

Do not make any adjustments to the

product.

▶

Do not start up the product.

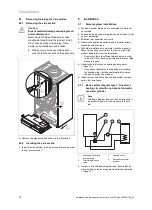

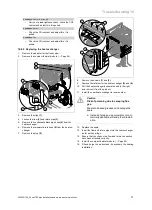

A

B

D

C

1.

Close the gas stopcock.

2.

Alternatives 1 / 2

‒

Measuring the gas pres-

sure at the gas valve assembly:

▶

Undo the test nipple screw

(A)

on the gas valve

assembly.

▶

Connect a digital manometer or U-tube manometer

(B)

.