7 Start-up

24

Installation and maintenance instructions ecoTEC plus 0020261188_00

2.

Alternatives 2 / 2

‒

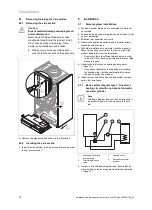

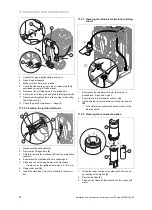

Measuring the gas pres-

sure at the gas connection:

▶

Undo the test nipple screw

(C)

at the gas connec-

tion.

▶

Connect a digital manometer or U-tube manometer

(D)

.

3.

Open the gas stopcock.

4.

Open the hydraulic circuit's valves.

5.

Start up the product with the check programme

P.01

.

6.

Measure the gas flow pressure in comparison with the

atmospheric pressure.

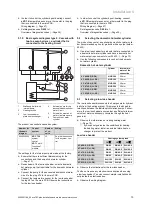

Gas connection pressure/gas flow pressure

difference for G20

Permitted gas flow

pressure that is

measured at point

(D)

Permitted gas flow

pressure that is

measured at point

(B)

VC 406/5-5

(E-DE)

1.70 … 2.50 kPa

(17.00

… 25.00 mbar)

1.60 … 2.40 kPa

(16.00

… 24.00 mbar)

VC 476/5-5

(E-DE)

1.70 … 2.50 kPa

(17.00

… 25.00 mbar)

1.60 … 2.40 kPa

(16.00

… 24.00 mbar)

VC 636/5-5

(E-DE)

1.70 … 2.50 kPa

(17.00

… 25.00 mbar)

1.55 … 2.35 kPa

(15.50

… 23.50 mbar)

Gas connection pressure/gas flow pressure

difference for G25

Permitted gas flow

pressure that is

measured at point

(D)

Permitted gas flow

pressure that is

measured at point

(B)

VC 406/5-5

(E-DE)

2.00 … 3.00 kPa

(20.00

… 30.00 mbar)

1.85 … 2.83 kPa

(18.50

… 28.30 mbar)

VC 406/5-5

(LL-DE)

2.00 … 3.00 kPa

(20.00

… 30.00 mbar)

1.85 … 2.83 kPa

(18.50

… 28.30 mbar)

VC 476/5-5

(E-DE)

2.00 … 3.00 kPa

(20.00

… 30.00 mbar)

1.85 … 2.83 kPa

(18.50

… 28.30 mbar)

VC 476/5-5

(LL-DE)

2.00 … 3.00 kPa

(20.00

… 30.00 mbar)

1.85 … 2.83 kPa

(18.50

… 28.30 mbar)

VC 636/5-5

(E-DE)

2.00 … 3.00 kPa

(20.00

… 30.00 mbar)

1.85 … 2.85 kPa

(18.50

… 28.50 mbar)

VC 636/5-5

(LL-DE)

2.00 … 3.00 kPa

(20.00

… 30.00 mbar)

1.85 … 2.85 kPa

(18.50

… 28.50 mbar)

Gas connection pressure/gas flow pressure

difference for G31

Permitted gas flow

pressure that is

measured at point

(D)

Permitted gas flow

pressure that is

measured at point

(B)

VC 406/5-5

(E-DE)

2.50 … 4.50 kPa

(25.00

… 45.00 mbar)

2.45 … 4.45 kPa

(24.50

… 44.50 mbar)

VC 406/5-5

(LL-DE)

2.50 … 4.50 kPa

(25.00

… 45.00 mbar)

2.45 … 4.45 kPa

(24.50

… 44.50 mbar)

VC 476/5-5

(E-DE)

2.50 … 4.50 kPa

(25.00

… 45.00 mbar)

2.45 … 4.45 kPa

(24.50

… 44.50 mbar)

VC 476/5-5

(LL-DE)

2.50 … 4.50 kPa

(25.00

… 45.00 mbar)

2.45 … 4.45 kPa

(24.50

… 44.50 mbar)

VC 636/5-5

(E-DE)

2.50 … 4.50 kPa

(25.00

… 45.00 mbar)

2.35 … 4.35 kPa

(23.50

… 43.50 mbar)

VC 636/5-5

(LL-DE)

2.50 … 4.50 kPa

(25.00

… 45.00 mbar)

2.35 … 4.35 kPa

(23.50

… 43.50 mbar)

7.

Decommission the product.

8.

Close the gas stopcock.

9.

Remove the manometer.

10. Tighten the test nipple screw

(A)

or

(C)

.

11. Open the gas stopcock.

12. Check the test nipple for gas tightness.

Conditions

: Gas flow pressure not in the permissible range

▶

If you are unable to eliminate the fault, contact the gas

supply company.

▶

Close the gas stopcock.

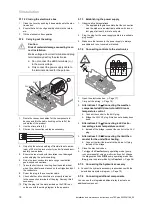

7.8.3

Checking the CO

₂

content and, if

necessary, adjusting it (air ratio setting)

1.

Ensure that the heating circuit valves are open.

2.

Start up the product with the check programme

P.01

.

3.

Wait at least five minutes until the product reaches its

operating temperature.

1

4.

Measure the CO

₂

content at the flue gas analysis point

(1)

.

5.

Compare the measured value with the corresponding

value in the table.