Instructions for Use, Installation and Servicing ecoMAX pro

20

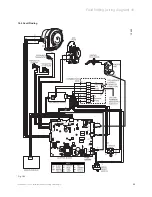

12 Commissioning

Please ensure the “Benchmark” service record is

completed and left with the user.

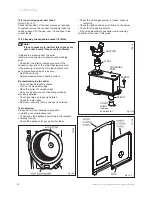

Note!

During commissioning the overheat thermostat

may trip before air is completely removed from

the system. If this occurs the boiler can be reset

by pushing the manual reset button on the

overheat thermostat (see fig 12.1).

12.1 Preliminaries - All Systems

A competent person should carry out commissioning, in

accordance with the current issue of BS 6798.

Make sure that the system has been thoroughly flushed

out with cold water.

Refill the system with water, making sure that all the air

is properly vented from the system and pump, fig 12.1

shows vent point.

Before operating the boiler check that all external

controls are calling for heat.

12.2 Sealed Systems

Fill the system until the pressure gauge registers the

recommended pressure. Clear any air locks and check

for leaks.

Check the operation of the safety valve, preferably by

allowing the water pressure to rise until the valve lifts.

This should be within ± 0.14 bar, of the preset pressure.

Where this is not possible a manual check should be

carried out.

Release the cold water to the initial design pressure.

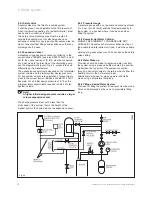

12.3 Gas supply

Isolate the boiler from the mains electrical supply.

The complete gas installation including the gas meter

must be isolated, tested for soundness and purged in

accordance with BS 6891, in IE the current edition of

IS 813.

The gas supply to the boiler can be purged by

slackening the gas service union connection beneath

the boiler. Ensure that there is adequate ventilation,

extinguish all naked flames and do not smoke whilst

purging.

After purging, the gas service union connection must

be re tightened and tested for soundness. (The boiler

itself does not require purging as this will be done by the

automatic burner sequence control).

The gas valve is factory set for natural gas (G20) and

should need no adjustment. (LPG G31 ecoMax pro 28E

only) should be adjusted as described Section 13 Natural

gas to LPG conversion. It should be checked that the

supply pressure is 20mb when the boiler is firing at full

rate. This can be achieved by checking the inlet pressure

at the pressure test point on the gas valve shown in fig

12.2.

Caution!

Before operating the boiler check the data

badge and ensure that the correct gas type

appliance has been installed.

PRESSURE TEST

POINT

ELECTRICAL

PLUG

GAS CONTROL

VALVE

THROTTLE

OFFSET

ADJUSTMENT

Fig 12.2

12701

VENT POINT

FLOW

PIPE

OVERHEAT

THERMOSTAT

FLOW

THERMISTOR

RETURN

THERMISTOR

Fig 12.1

12700

Summary of Contents for ecoMAX pro 18E

Page 37: ...Instructions for Use Installation and Servicing ecoMAX pro 37 Declaration of Conformity 17...

Page 38: ...Instructions for Use Installation and Servicing ecoMAX pro 38...

Page 39: ...Instructions for Use Installation and Servicing ecoMAX pro 39...

Page 40: ...0020005557_04 GB 08 2006 Subject to alteration...