Appendix

0020271943_00 atmoMAG Installation and maintenance instructions

23

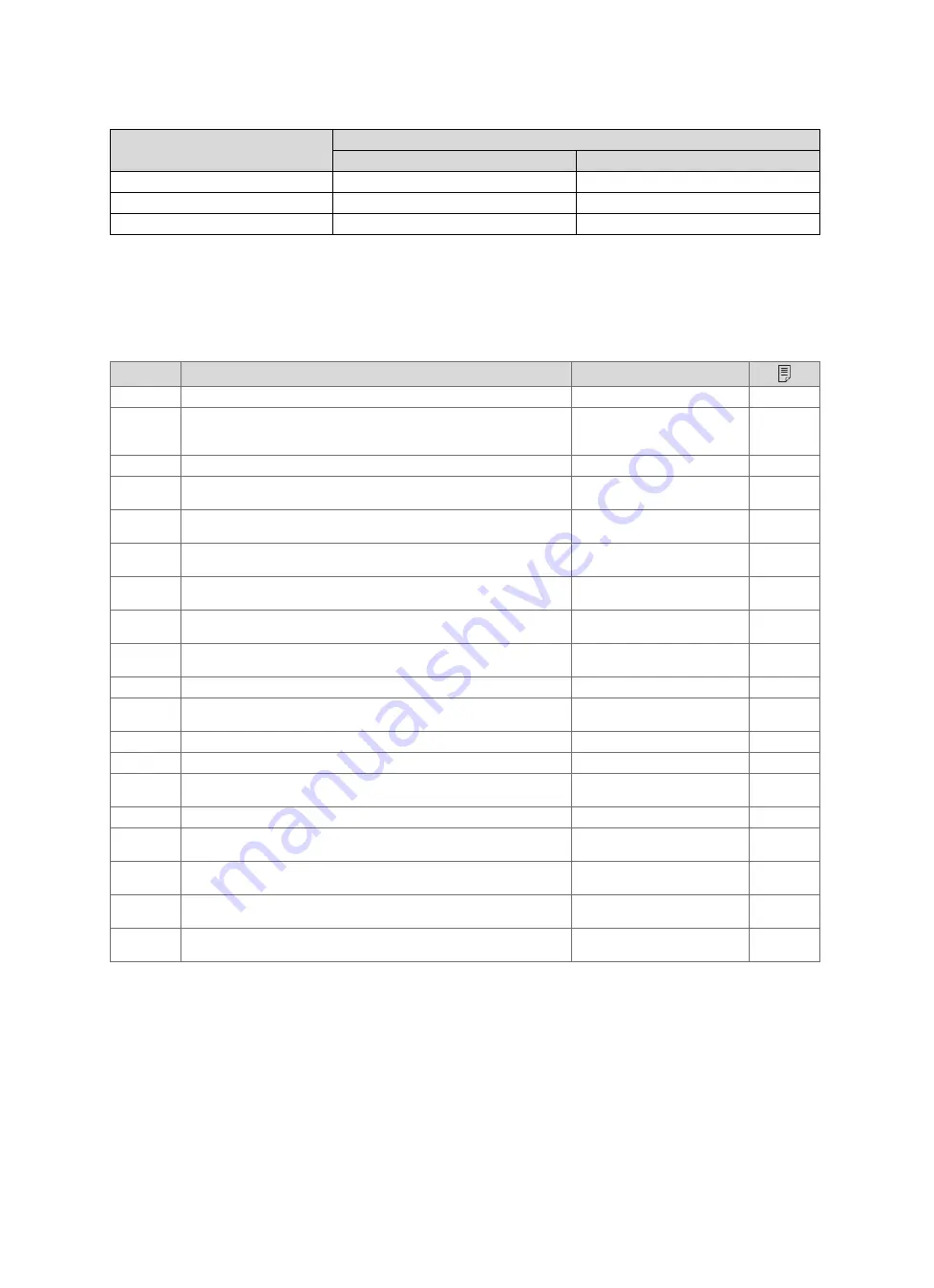

Burner pressure

Gas family

Burner pressure for nominal heat input

11-4/1

14-4/1

Natural gas 2E (G20)

1.12 kPa (11.2 mbar)

1.38 kPa (13.8 mbar)

Natural gas 2E+ (G25)

1.48 kPa (14.8 mbar)

1.85 kPa (18.5 mbar)

Liquid gas 3P (G31)

3.17 kPa (31.7 mbar)

3.45 kPa (34.5 mbar)

E

Inspection and maintenance interval

The table below lists the manufacturer requirements with respect to minimum inspection and maintenance intervals. If na-

tional regulations and directives require shorter inspection and maintenance intervals, you should observe these instead of

the intervals listed. Each time inspection and maintenance work is carried out, carry out the required preparatory and com-

pletion work.

#

Maintenance work

Interval

1

Remove any dirt from the product

Annually

2

Check the flue gas sensor for dirt and damage. Checking that the flue

gas sensor is working correctly by completely blocking the flue gas with

flue gas restrictors

Annually

3

Checking the safety cut-out for dirt and damage

Annually

4

Cleaning the burner

If required, at least every

2 years

16

5

Cleaning the heat exchanger

If required, at least every

2 years

18

6

Cleaning the injector rail

If required, at least every

2 years

16

7

Cleaning the down-draught diverter

If required, at least every

2 years

17

8

Check the ignition electrode and thermocouple for damage, and replace

any bent and damaged components

Annually

9

Checking the seals on the test nipples for damage and replacing any

damaged seals

Annually

10

Checking that the water flow switch (micro switch) is working correctly

Annually

11

Carry out a test operation on the product, incl. domestic hot water gener-

ation

Annually

12

Checking leak-tightness

Annually

14

13

Checking the heat input

Annually

18

14

Check the flame pattern. Flames must not touch the heat exchanger shaft

If required, at least every

2 years

15

Visually inspecting the test nipples and hoses

Annually

16

Interrupt the thermocurrent by disconnecting the connection between the

thermocouple and holding magnet. The product must be shut down

Annually

17

Checking the water valve

If required, at least every

2 years

18

18

Logging flue-gas measured values and any maintenance work that was

carried out

Annually

19

Checking the product to see if flue gas is escaping at the down-draught

diverter, with the doors and windows closed and the casing installed

Annually