page 46 of 56

Assembling the connecting hoses

➨

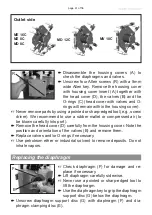

Slip the hoses (O) onto the hose connec-

tors by turning the fittings (Q) with an open-

ended wrench w/f 14 (w/f 16 at outlet).

➨

Tighten the union nuts (N) of the hose con-

nections at the pump heads with an open-

ended wrench w/f 17.

+

Tighten union nuts first by hand and then

tighten one full turn using the open ended

wrench.

If the pump does not achieve the ultimate vacuum:

- Whenever the diaphragms and valves have been replaced, a break-in

period of several hours is required before the pump achieves its ulti-

mate vacuum.

- In case of an unusual noise, switch off pump immediately and check

clamping disc positions.

If the specified ultimate vacuum is not achieved, and if this does not

change after the break-in period:

Check hose connectors at pump heads for leaks. If necessary recheck

valve seats and pump chambers.

Checking the ultimate vacuum

➨

After any intervention at the equipment (e.g., repair / maintenance)

the ultimate vacuum of the pump has to be checked. Only if the pump

achieves its specified ultimate vacuum, the pump’s leak rate is low

enough to ensure that no explosive atmospheres will occur in the inte-

rior of the equipment.

Summary of Contents for ME 16C

Page 54: ...page 54 of 56...

Page 55: ...page 55 of 56...