page 42 of 56

➨

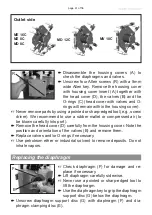

Check for washers (H) between the diaphragm support disc (G) and

the connecting rod (I) . Do not mix the washers from the different pump

heads, since these are set at the factory to ensure proper pump per-

formance. Make sure that the original number is reassembled at the

individual pump head.

+

Too few washers: The pump will not attain vacuum specification. Too

many washers: Diaphragm clamping disc will hit head cover, causing

noisy operation and possibly causing the pump to seize up.

+

If the old diaphragm is difficult to separate from the diaphragm support

disc, immerse assembly in naphtha or petroleum ether. Do not inhale

vapors!

➨

Position new diaphragm (F) between dia-

phragm clamping disc with square head

screw (E) and diaphragm support disc (G).

+

Note

: Position diaphragm with pale side

towards diaphragm clamping disc (facing

pump chamber).

+

Make sure that the square head screw of the diaphragm clamping disc

is correctly seated in the guide hole of the diaphragm support disc.

➨

Lift the diaphragm at the side. Place the diaphragm carefully together

with diaphragm clamping disc and diaphragm support disc in the dia-

phragm key.

+

Avoid damage of the diaphragm; do not excessively bend or crease

the diaphragm too much.

E

G

F

➨

Assemble the original number of washers

(H) between diaphragm support disc (G)

and connecting rod (I).

➨

Screw diaphragm clamping disc (E), dia-

phragm (F), diaphragm support disc (G)

and washers (H) to connecting rod (B).

➨

Optimum torque for the diaphragm support disc: 4.4 ft

.

lb

f

(6 Nm), it is

recommended to use a torque wrench. Attach Allen key to diaphragm

key (hexagonal bolt 6 mm wide).

Note: Never use the diaphragm key with any additional tools like tongs

or Allen keys without appropriate torque limitation.

F

E

Summary of Contents for ME 16C

Page 54: ...page 54 of 56...

Page 55: ...page 55 of 56...