page 38 of 56

Ensure that maintenance is done only by suitably

trained and supervised technicians.

The valves and diaphragms as well as the motor capac-

itors are wear parts. If the rated ultimate vacuum is no

longer achieved or in case of increased noise level, the

pump interior, the diaphragms and the valves must be

cleaned and the diaphragms and valves must be checked

for cracks or other damage.

All bearings are encapsulated and are filled with long-life

lubricant. Under normal operating conditions, the drive

system is maintenance free.

In demanding circumstances, it may be efficient to

check and clean the pump heads on a regular basis. In

normal use, the lifetime of the diaphragms and valves

is typically 15,000 operating hours.

- Prevent internal condensation, transfer of liquids or

dust. The diaphragms and valves will be damaged if

liquid is pumped in significant amount.

- Carry out maintenance frequently if the pump is ex-

posed to corrosive media or in case of deposits.

- Regular maintenance will improve the lifetime of the

pump and also protect both users and the environment.

NOTICE

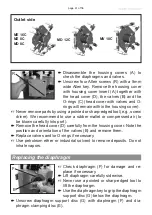

Set of seals (diaphragms, valves, O-rings) ...............................................

20696821

Set of seals for ME 16C (diaphragms, valves) ....................................

8x

20696813

Diaphragm key (w/f 66) ............................................................................

20636554

Tools required (metric):

- Phillips screwdriver size 2

- Open end wrench width 14 / 16 / 17

- 5 mm wide Allen key

- Diaphragm key width 66 mm

Summary of Contents for ME 16C

Page 54: ...page 54 of 56...

Page 55: ...page 55 of 56...