Procedures after repair

24h on-call service phone: +358 (0)40 83 71 150

112

6

12. START-UP AFTER REPAIR

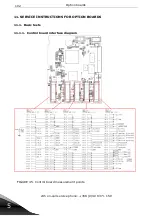

12.1. An external DC power without the motor for FR4 to FR13

Before proceedings to test the unit, check all of the parts, wiring and motor connec-

tions visually, to see that they are correct. There will be dangerously high voltages

present during this test.

12.2. Testing with a DC suppply without the motor connection

Switch off the DC power supply

Connect the power supply's DC+ to the unit's B+ main terminal. Locate an internal

place for the DC+ connection, if the drive does not have a DC+ terminal.

Connect the power supply's DC- to the unit's B- main terminal. Locate an internal

place for the DC- connection, if the drive does not have a DC- terminal.

Set the power supply voltage setting to zero and switch on the DC -power supply.

Increase the voltage slowly to the units nominal DC-voltage (1,35 x Un)

Read the following monitoring and system info values:

The Voltage of the DC link is 1.8 (the same as the supplied DC voltage).

The Unit temperature is V1.9 (estimate, if it corresponds to environmental tempera-

ture)

The Software version (is the same as loaded into the unit)

Ready state or not

Set parameter 2.7.4 (ID 730) to 0 in the standard application. This disables the input

line supervision.

Set the drive to RUN state.

Change the reference frequency from 0 to 50 Hz. Check the output frequency.

Increase the DC voltage to the tripping limit. Check for the over-voltage fault (F2)

indication on the display.

NOTE! DO NOT EXCEED OVERVOLTAGE TRIPPING LIMIT!

Switch off the DC power supply and wait until the DC link has discharged!