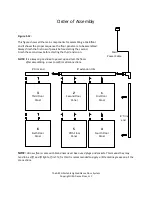

Screwing the Floor Panels Together

One inch stainless steel screws are used to

hold the floor pa els to ea h other a d keep the pa el’s le el

with each other. Screws should never ever be t

ight. At first the s re s should o l e started a d kept

loose during assembly as shown in figure 1-7. This will keep the panels free to move as the panels

square up to each other. Only after all screws have been started in all the panels and edging the screws

may be secured. If you are installing beveled edging start all those screws as well before securing any

other screws.

NOTE:

A power drill may be used to secure screws only if it has a ratchet drive set at low torque.

Securing a screw does not mean to tighten it. Securing a screw means that the top of the

s re ’s head is le el ith or elo the da e floor surfa e as sho

i figure

-8.

NOTE:

If a bolt binds, cross threads

or won’t go in straight…

skip it. It is ok to have a missing bolt

here and there then to cross thread or bind a screw.

Figure 1-7

Dance Floor surface

The cutaway drawing on the right shows

the screw in the

started

position.

Figure 1-8

This drawing shows the screw in the

secured

position. Notice there is room

to allow for flexing and movement.

Figure 1-9

This drawing shows the screw

too tight

.

This can cause the floor to crack.

The ARCH Portable Lighted Dance Floor System

Copyright USA Dance Floor, LLC