Basic - Information

Q3 240-840A

4

G

en

er

al

a

nd f

ea

tur

es

2.3

General and features

This manual describes the basic unit and

is only in connection with the manual of the control electronics

(e.g. REGxx) valid.

Manual use in connection with:

- an analogue control

REGxx

- field regulation internal

QS-F

- field regulation external

F2xx

- options

Build

- switch cabinet mounting a

- according to the VDE, DIN and EU regulations

- standard control electronics REG

- intrinsically safe power section with current control loop

- controlled or uncontrolled field supply unit

- optional units

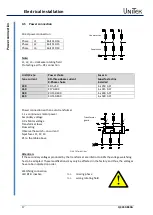

Galvanic isolation between

- the power section and the housing

- the power section and the control electronics

The distance of air gaps and leakage paths adhere to the VDE standards (>8mm).

Components

- fully insulated thyristor modules, comfortably over-dimensioned

- only components customary in trade and industrially standardized are used

- high-quality bases for the IC with external connections

- LED displays

- precision potentiometers for fine adjustments

- plug-in jumpers for the system set-up