11.3 -

Level 3 (or higher) maintenance

Maintenance at this level requires specific skills, qualifications,

tools and expertise. Only the manufacturer, his representative or

authorised agent are permitted to carry out this work.

This maintenance work relates to the following:

-

Replacement of major components (compressor, water heat

exchanger),

-

Operations on the refrigerant circuit (handling refrigerant),

-

Modification of factory-set parameters (change of application),

-

Moving or dismantling the heat pump,

-

Any operation due to proven lack of maintenance,

-

Any operation covered by the warranty.

To reduce waste, the refrigerant and the oil must be transferred

in accordance with applicable regulations, using methods

that limit refrigerant leaks and pressure drops and with

materials that are suitable for the products.

Any leaks detected must be repaired immediately.

The compressor oil that is recovered during maintenance

contains refrigerant and must be treated accordingly.

Pressurised refrigerant must not left open to purge.

For a period of up to one day, cap all openings. If open for

longer, blanket the circuit with an inert gas (e.g. nitrogen) for

longer durations.

11.4 -

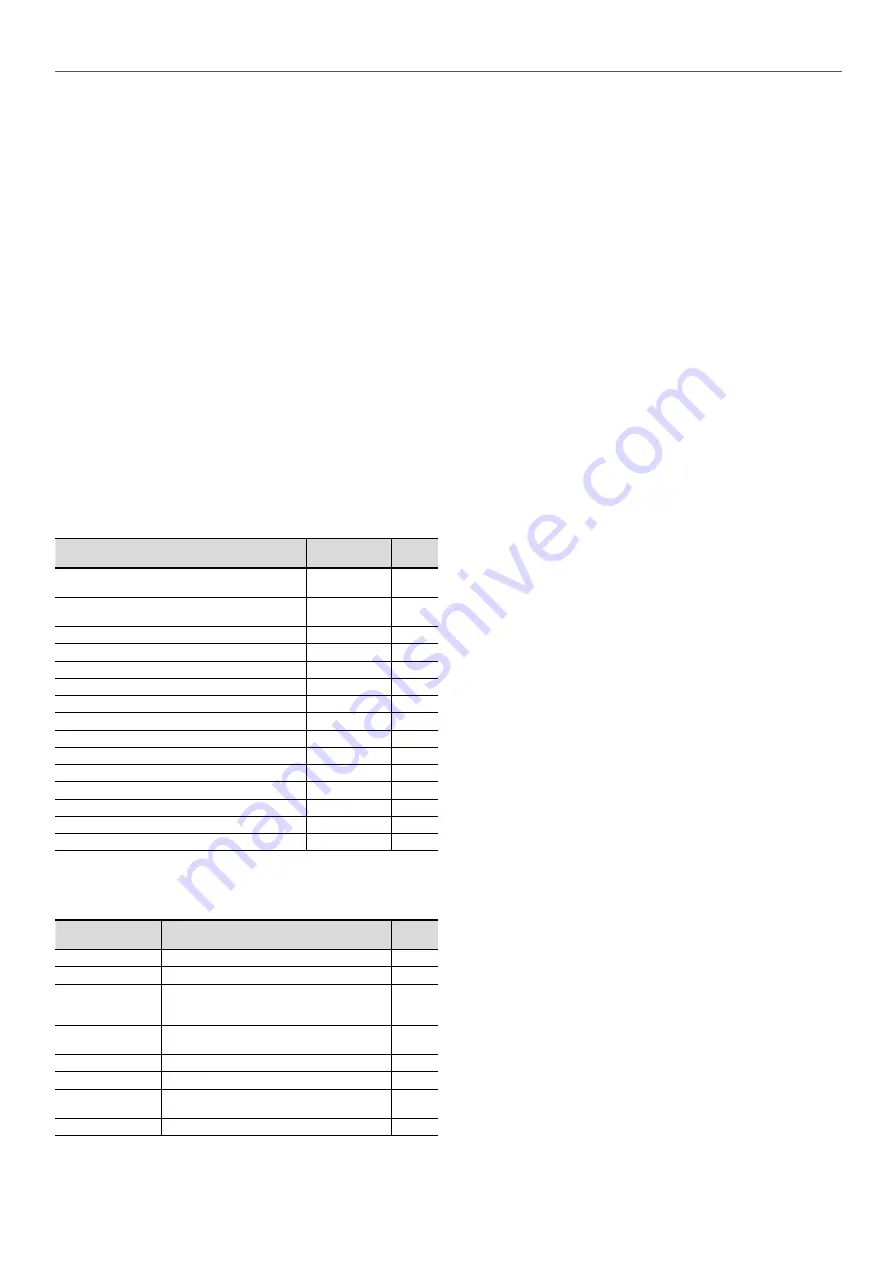

Tightening torques for the main electrical

connections

Component

Designation

in the unit

Value

(N.m)

Welded screw PE, customer connection (earth

connection)

-

40

Screw terminal, fuse holder

FU1, FU2,

FU3, FU4

10

Screw terminal, fuse holder

FU100

0,8-1,2

Screw terminal, compressor contactor

KM1-->KM12 3 - 4,5

Brass screw M6, compressor ground

EC-

5

M6 screw, compressor connection

EC-

5

Screw terminal, circuit breakers

QM-, QF-

2

Screw terminal, pump contactor

KM90, KM90A

2,5

M8 screw customer connection (size 160-270)

QS100

15 - 22

M10 screw customer connection (size 310-430)

QS100

30 - 44

M12 screw customer connection (size 470-520)

QS100

50 - 75

Screw terminal, circuit breakers(taille 160-330)

QF100

3,2-3,7

Screw terminal, circuit breakers (taille 380-520)

QF100

8-10

Screw terminal, fuse holder 32A (opt231)

Fu-

2,5

Screw terminal, fuse holder 100A (opt231)

Fu-

3,5 - 4

11.5 -

Tightening torques for the main bolts and

screws

Screw type

Use

Value

(N.m)

Metal screw D=4.8

Air coil sub-assembly, casing, supports

4,2

Metal screw D=6,3 Plastic grille volute

4,2

Taptite M10 screw

Air coil sub-assembly, chassis-structure,

electrical box fixing, plate heat exchanger

and pump

30

Taptite M6 screw

Pipe supports, enclosure, variable

frequency drive supports

7

H M6 screw

Pipe clip

10

H M10 nut

Compressor chassis, Compressor fixing

30

Oil equalisation

screw

Oil equalisation line

145

M16 screw

Refrigerant accumulator tank flange

180

11.6 -

Air coil

We recommend that coils with fins are inspected regularly to check

the degree of cleanliness. This depends on the environment where

the unit is installed, in particular urban and industrial sites, and for

units installed near trees that shed their leaves.

Recommendations for maintenance and cleaning of RTPF

coils:

-

Regularly cleaning the coil surface is essential for correct

unit operation.

-

Eliminating contamination and removal of harmful residue

will increase the operating life of the coils and the unit.

-

Specific recommendation in case of snow: For long term

storage, regularly check that no snow has accumulated on

the coil.

-

Use appropriate PPE including safety glasses and/or mask,

waterproof clothes and safety gloves. It is recommended that

clothing that covers the whole body is worn.

Level 1 cleaning

-

Remove all foreign objects or fragments/debris attached to

the coil surface or wedged between the chassis and the

supports.

-

Use a low pressure dry air jet to remove all traces of dust

from the coil, or use a brush in a careful, vertical motion.

Level 2 cleaning

-

Carry out the level 1 cleaning operations.

-

Clean the coil using suitable products.

Specific Carrier-approved products for cleaning RTPF coils

with untreated fins are available from the Carrier spare parts

network. The use of any other product is strictly prohibited.

After the cleaning product is applied, rinsing with water is

mandatory (see Carrier standard RW01-25).

IMPORTANT: Never use a pressure water spray without a large

diffuser. Concentrated and/or rotating water jets are strictly

prohibited.

Never use a fluid with a temperature above 45°C to clean the

air heat exchangers.

Correct and frequent cleaning (approximately every three

months) will prevent two-thirds of corrosion problems.

Protect the electrics box during cleaning operations.

11.7 -

Water heat exchanger maintenance

Check that:

-

The insulation has not been detached or torn during

operations,

-

The heaters and probes are operating and correctly

positioned in their support,

-

The water-side connections are clean and show no sign of

leakage,

-

The period inspections required by the local regulations have

been carried out.

11 - STANDARD MAINTENANCE

57

Summary of Contents for Carrier 30RQM 160

Page 63: ......