268882-UIM-A-0407

Unitary Products Group

15

VENT SYSTEM

This furnace is certified to be installed with one of two possible vent

configurations.

1.

Horizontal vent system. This vent system can be installed com-

pletely horizontal or combinations of horizontal, vertical, or offset

using elbows.

2.

Vertical vent system. This vent system can be installed completely

vertical or a combination of horizontal, vertical, or offset using

elbows.

HORIZONTAL VENT APPLICATIONS AND

TERMINATION

When selecting the location for a horizontal combustion air / vent termi-

nation, the following should be considered:

1.

Observe all clearances listed in vent clearances in these instruc-

tions.

2.

If installing a vertical venting system through any unconditioned

space such as an attic or crawl space, it must be completely insu-

lated to a minimum "R" value of 3.5 either by blown in or wrapped

insulation.

3.

Termination should be positioned where vent vapors will not dam-

age plants or shrubs or air conditioning equipment.

4.

Termination should be located where it will not be affected by wind

gusts, light snow, airborne leaves or allow recirculation of flue

gases.

5.

Termination should be located where it will not be damaged or

exposed to flying stones, balls, etc.

6.

Termination should be positioned where vent vapors are not objec-

tionable.

7.

Horizontal portions of the vent system must slope upwards and be

supported to prevent sagging. The vent system may be supported

by the use of clamps or hangers secured to a permanent part of

the structure every 4 ft. (1.22 m) and that is is angled a minimum

of 1/4" per foot (0.635 cm/m) so that condensate will flow towards

the furnace.

8.

Sealed combustion air systems must be installed so the vent and

the combustion air pipes terminate in the same atmospheric zone.

Refer to Figure 18.

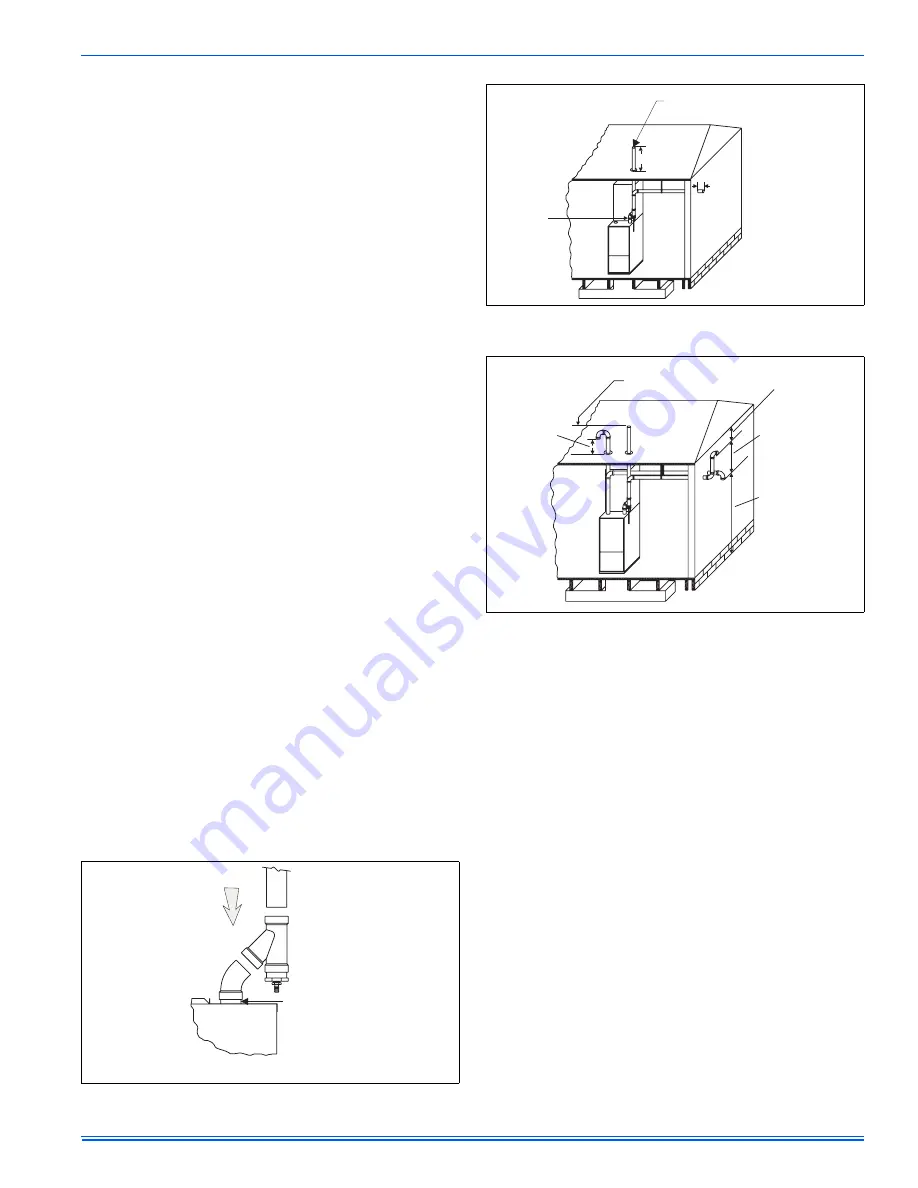

DOWNFLOW VENT ASSEMBLY

1.

Place the 2” (5.1 cm) 45° PVC street elbow on the vent connection

shown in Figure 16.

2.

Place the 2” (5.1 cm) PVC WYE (“Y”) assembly on the 2” (5.1 cm)

45° PVC street elbow as shown in Figure 16.

3.

Locate the rubber condensate hose in front of the blower access

panel.

4.

Slide the hose through the hole in the top cover, and insert the

hose on to the barbed fitting on the bottom of the 2” (5.1 cm) PVC

WYE (“Y”) assembly as shown in Figure 16.

Place 2” rubber sleeve of PVC pipe at top of furnace and place a 2”

piece of PVC pipe in the other end of the 2” rubber sleeve.

VERTICAL VENT APPLICATIONS AND

TERMINATION

Roof mounted vertical terminals may be field fabricated. Standard PVC/

SRD fittings may be used. If installing a vertical venting system through

any unconditioned space such as an attic or crawl space it must be

completely insulated to a minimum "R" value of 3.5.

1.

Observe all clearances listed in vent clearances in these instruc-

tions.

2.

Termination should be positioned where vent vapors are not objec-

tionable.

3.

Termination should be located where it will not be affected by wind

gusts, light snow, or allow recirculation of flue gases.

4.

Termination should be located where it cannot be damaged,

plugged or restricted by tree limbs, leaves and branches.

5.

Horizontal portions of the vent system must slope upwards and be

supported to prevent sagging. The vent system may be supported

by the use of clamps or hangers secured to a permanent part of

the structure every 4 ft. (1.22 m) and that it is angled a minimum of

1/4" per foot (0.635 cm/m) so that condensate will flow towards the

furnace.

FIGURE 16:

Downflow Vent Assembly

DOWNFLOW

2” (5.08 cm)

VENT PIPE

2” PVC

WYE

2” PVC

45°

ELL

FURNACE

VENT PIPE

RETURN

AIR

FIGURE 17:

Termination Configuration - 1 Pipe (Modular Installations

Only)

FIGURE 18:

Termination Configuration - 2 Pipe

12” MIN.

12” MIN.

MAINTAIN 12” MINIMUM CLEARANCE

ABOVE HIGHEST ANTICIPATED SNOW

LEVEL. MAXIMUM 24” ABOVE ROOF.

2” RUBBER

SLEEVE

COUPLING

MAINTAIN 12”

MINIMUM

CLEARANCE

ABOVE HIGHEST

ANTICIPATED

SNOW LEVEL.

12” VERTICAL SEPARATION

BETWEEN COMBUSTION AIR

AND VENT

12” MINIMUM

BELOW

OVERHANG

12” MINIMUM

SEPARATION

BETWEEN BOTTOM

OF COMBUSTION

AIR PIPE AND

BOTTOM OF VENT

MAINTAIN 12”

MINIMUM CLEARANCE

ABOVE HIGHEST

ANTICIPATED SNOW

LEVEL OR GRADE,

WHICHEVER IS

HIGHER