43

Tracking the Conveyor Belt

The

iColor coater

is designed for a long life and production. The Conveyor Belt has been tracked in

manufacturing based on normal operating conditions.

To test if your belt is tracking correctly, turn the Belt & UV on and let

it

run for approximately

5 - 10

minutes under normal operating conditions (i.e. 50% speed & 75% UV intensity). If the belt ap

-pears

to walk in one direction or the other, perform the following steps.

1.

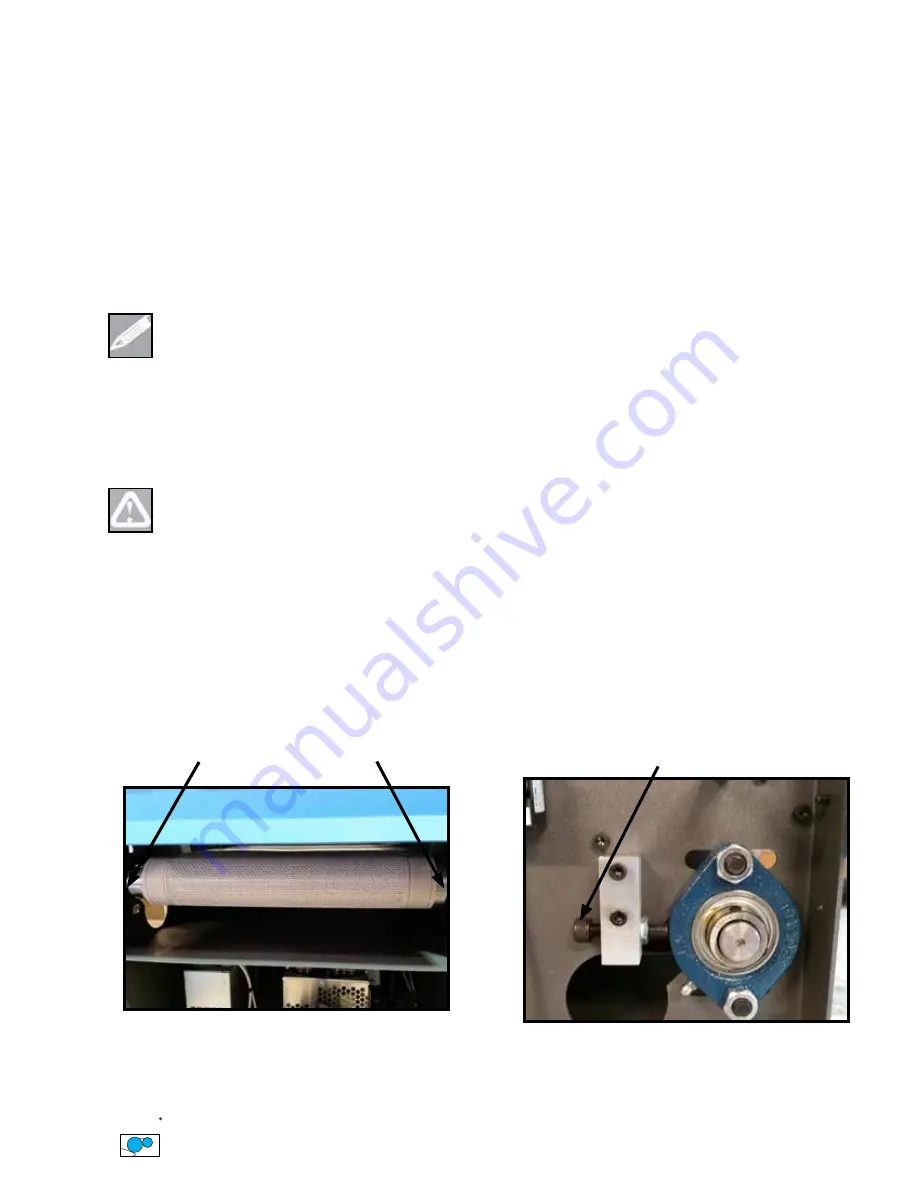

Loosen the (2) two Flange Bearing Locking Nuts, on either side, with a 17mm wrench

NOTE:

The Rear Panel is removed from the image below to show a clear view of the Flange

Bearing Locking Nuts.

2. Facing the belt, If the belt is walking to the Right, tighten the Right Tracking Bolt or Loosen the Left

Tracking Bolt approximately one eighth of a turn.

3. Facing the belt, If the belt is walking to the Left, tighten the Left Tracking Bolt or Loosen the Right

Tracking Bolt approximately one eighth of a turn.

CAUTION:

Do Not Overtighten the Tracking Bolts as this will damage the Conveyor Belt. The

belt should be just tight enough to hold with some force but still rotate.

4. After making your adjustments, let the system run for 5 minutes and evaluate. Continue if necessary.

5. Once the belt is tracking, tighten the (2) two Flange Bearing Locking Nuts, on either side, with a

17mm wrench.

6. Turn equipment Off or continue your production.

Figure - Belt Tracking Flange Bearing Bolts

Figure - Belt Tracking Adjustment Bolt

Belt Tracking Adjustment Bolt

Flange Bearing Bolts