14

PG-I Series | Version 1.03

Commissioning

8.1 Unpacking

Step 1: Place the carton on a stable and level surface.

Step 2: Remove the packaging from the generator.

Step 3: Check the generator and make sure that it has not

been damaged in transit. If any damage is found,

contact the service department or the dealer. In

this case, do not fill the generator with fuel or at-

tempt to start it.

8.2 Check and fill in fuel

The generator is supplied without fuel. Make sure that

enough fuel has been filled in before starting the generator.

Proceed as follows to top up fuel:

Step 1: Switch off the generator and disconnect the

consumer.

Step 2: Close fuel cock.

Step 3: Open fuel cap and check fuel level.

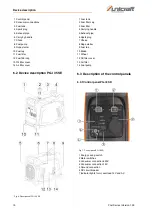

Fig. 14: Check filling level

Step 4: Clean the area around the tank filler neck.

Step 5: Fill the fuel tank with petrol. Use unleaded regular

gasoline with a minimum octane number of 85.

Step 6: Close the fuel cap.

Step 7: Wipe up spilled petrol!

DANGER!

Starting the engine with an insufficient oil level can

cause serious damage!

Check the fuel level:and use only clean and water-

free fuel.

The fuel is highly flammable and explosive under cer-

tain conditions. Refuel in a well ventilated area and

with the engine switched off. Do not smoke or use an

open fire while refuelling.

Never work with the generating set before the air fil-

ter has been inserted, otherwise the life of the engine

and the generating set will be reduced.

NOTE!

Before putting the generator into operation for the

first time, observe the following points.

- Make sure that the generator is placed on a flat, ho-

rizontal and stable surface.

- Check fuel and engine oil.

- Make sure that no power consumers are connected

to the generator.

- When starting the petrol engine, switch on the

choke for cold starting.

- To start generators with pullstarters, pull the starter

slowly out until resistance is felt, then pull jerkily.

CAUTION!

Do not fill the tank in enclosed spaces.

Never fill the tank while the machine is running or still

hot.

Do not overfill the tank (do not fill up to the top of the

filler), fuel could leak due to engine vibrations. Cau-

tion: Fuel expands when heated!

Ensure that no fuel drips to the ground during filling.

Ensure that the fuel filler cap is correctly closed after

refuelling. If petrol has dripped onto the ground,

ensure that the area is dry before starting the engine.

Avoid direct physical contact with the fuel and do not

inhale vapours; keep out of the reach of children.

The petrol vapours are flammable. Never light ciga-

rettes or smoke when refuelling. Avoid naked flames

at all costs.

Use normal unleaded, new and clean fuel, with a

minimum octane number of 85.

Never mix oil with fuel.

DANGER!

Never fill the tank while the engine is running! The

generator must cool down for at least 2 minutes

before opening the tank cap.

Open the fuel cap slowly to equalize pressure.

Never mix oil with petrol! Never overfill the fuel tank.

Leave space for the gasoline to expand. Regularly

check the pipes, tank and cap for leaks or damage.

Replace if necessary.

If the generator is operated at an altitude of more

than 1500 m above sea level, petrol with at least 85

octane must be used.

NOTE!

When using the generator for the first time, press the

pump button 6 times after refuelling with petrol.