10 UNIBLOC-PD Operation & Service Manual: PD200-576

Always make sure the alignment with the drive unit is within proper tolerances. Misalignment between the pump, drive

and coupling will result in premature wear, increased operating temperature and noisier environment.

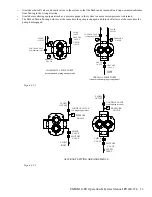

See figure 2.2.2 for vertical misalignment: Place shims under pump or drive; 0.25mm (0.01inch) max deviation.

See figure 2.2.3 for horizontal misalignment: Move pump or drive horizontally; 0.25mm (0.01inch) max deviation.

See figure 2.2.4 for angular misalignment: Rotate pump or drive; 1° max deviation

Avoid any direct contact with hot surfaces of the pump or drive unit. If the surface temperature of the system exceeds

68°C, the system must be marked with a warning sign for “hot surface.”

ALWAYS DISCONNECT THE POWER SUPPLY when performing any kind of maintenance. Make sure the power can

not be switched by locking it. Allow the pump and associated parts to cool down to a safe handling temperature.

Never operate the pump with either the suction side or the pressure side blocked.

Never operate the pump without the front cover installed properly

Always make sure any safety/relief valves are depressurized or relieved before dismantling.

Always ensure correct rotation of pump with flow direction before start.

Installation of safety equipment to prevent pump from exceeding maximum allowable pressure is recommended.

If an integrated safety relief valve is installed, do not allow extended periods of recirculation through the valve.

UNIBLOC-PUMP

can either integrate a safety valve with the front cover, or supply one as a separate unit.

Please contact your supplier.

Installation of a non-return device is recommended to prevent reverse flow in the pump when it is being turned

off.

UNIBLOC-PUMP

can supply a check valve as non-returning device. Please contact your supplier.

Check the pump and motor assembly for adequate oil prior start up.

Make sure the pump and pipe systems are clean and free from debris or any foreign material before start up.

Do not install the pump into a system where it may run dry (i.e. without a supply of pumped media) unless it is

assembled with a flushed shaft seal that is properly installed with a fully operational flushing system.

Installation of pressure gauges/sensors in conjunction with the pump’s suction and discharge connections is

recommended to be able to monitor the pump’s pressure.

When cleaning manually or by CIP, SIP methods, the operator must ensure that a suitable procedure is used in

accordance with the systems requirements.

If operating with a pulley, proper support must be selected to prevent excessive bearing wear and bending of the

shaft. See figure 2.2.5.

Additional safety guards are a must.

Figure 2.2.2

Figure 2.2.3

Figure 2.2.4

Figure 2.2.5

ATTENTION

ATTENTION

ATTENTION

ATTENTION

ATTENTION

ATTENTION

ATTENTION

ATTENTION

Summary of Contents for 54001010P20H6010T12E

Page 42: ...42 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Page 43: ...UNIBLOC PD Operation Service Manual PD200 576 43 UNIBLOC PUMP ...

Page 44: ...44 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Page 45: ...UNIBLOC PD Operation Service Manual PD200 576 45 UNIBLOC PUMP ...

Page 46: ...46 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Page 47: ...UNIBLOC PD Operation Service Manual PD200 576 47 UNIBLOC PUMP ...

Page 48: ...48 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Page 49: ...UNIBLOC PD Operation Service Manual PD200 576 49 UNIBLOC PUMP ...

Page 50: ...50 UNIBLOC PD Operation Service Manual PD200 576 3 ...

Page 51: ......

Page 52: ......