- 2 -

1.2 Product Features

1.2.1 Printer Standard Features

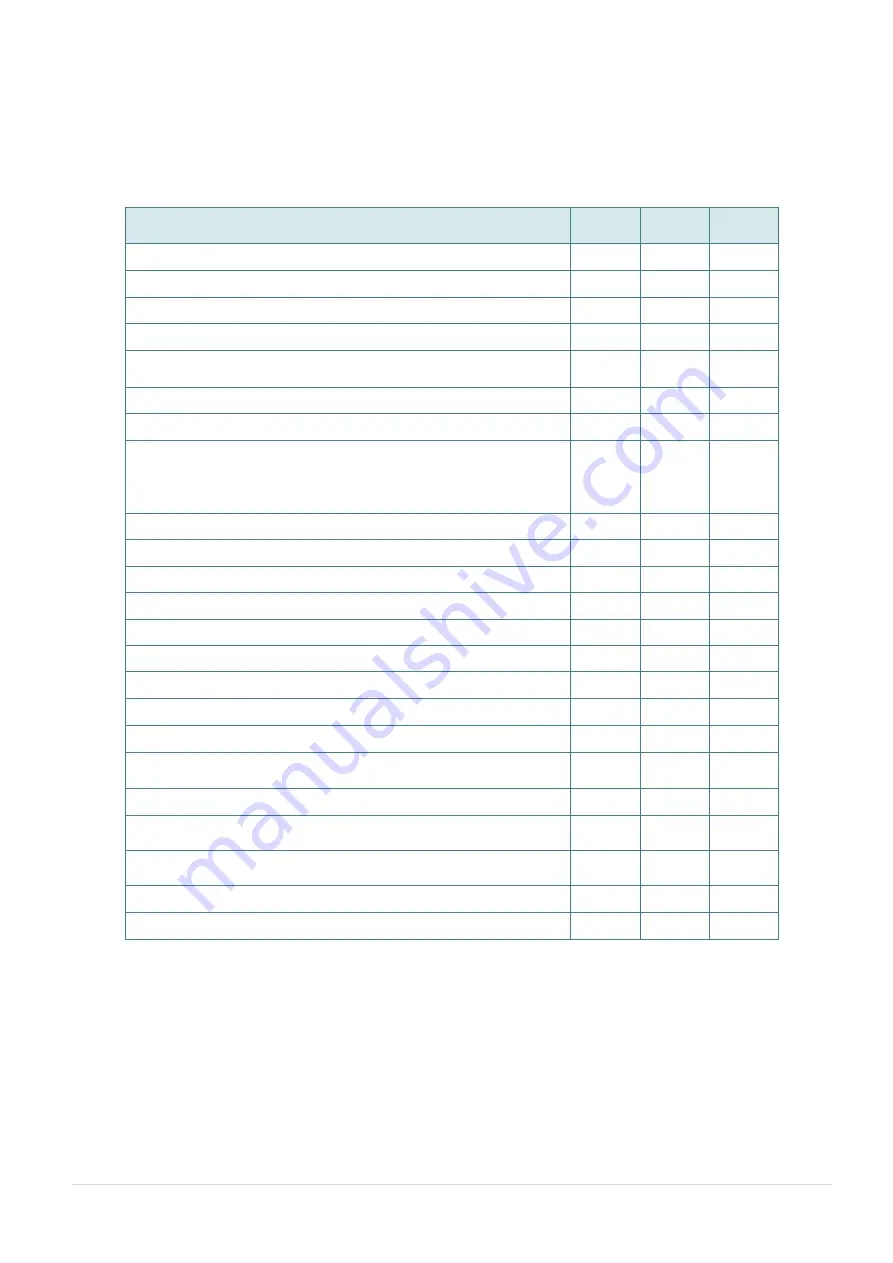

The printer offers the following standard features.

Product standard feature

200 dpi

model

300 dpi

model

600 dpi

model

Thermal transfer/ or direct thermal

○

○

○

LED icon panel with 1 button

○

○

-

3.5

” TFT LCD with 6 buttons

-

-

○

32-bit RISC high performance processor

○

○

○

Gap transmissive sensor (Fixed, center of offset 4 to right or 7

mm to left from center)

○

○

○

Black mark reflective sensor (Position adjustable)

○

○

○

See-through ribbon end sensor

-

-

○

Ribbon encoder sensor

For single printing, the label length should be more than 3 mm.

39.4mm is the threshold of ribbon low detection. The ribbon LED becomes

blinking if ribbon supply roll diameter is less than 39.4 mm.

○

○

○

Head open sensor

○

○

○

128MB Flash memory

○

○

○

128 MB DDR2 DRAM

○

○

○

Micro SD card reader for memory expansion, up to SDHC 32GB

○

○

○

RS-232 interface (Max. 115,200 bps)

○

○

○

USB 2.0 interface (Full speed mode)

○

○

○

Internal Ethernet print server (10/100 Mbps) interface

-

-

○

USB host

○

○

○

Real time clock & Buzzer

-

-

○

Standard industry emulations right out of the box including

Eltron

®

and Zebra

®

language support

○

○

○

Internal 8 alpha-numeric bitmap fonts

○

○

○

Fonts and bar codes can be printed in any one of the four

directions (0, 90,180, 270 degree)

○

○

○

Internal Monotype Imaging

®

true type font engine with one CG

Triumvirate Bold Condensed scalable font

○

○

○

Downloadable fonts from PC to printer memory

○

○

○

Clean print head warning

○

○

○

Summary of Contents for UltraLabel PRO-600

Page 1: ...USER S MANUAL UltraLabel PRO 600 THERMAL TRANSFER DIRECT THERMAL BAR CODE PRINTER...

Page 4: ...iii HAZARDOUS MOVING PARTS KEEP FINGER AND OTHER BODY PARTS AWAY...

Page 7: ...vi...

Page 8: ......

Page 26: ...18 Loading path for media...

Page 41: ...33 Numbers of download files Total available memory space Print head check pattern...