ULTIMATEAIR MODEL: 2000 DX

US Units

Metric Units

FLOW

200

–

2000 CFM

340 – 3740 CMH

ASE

92% - 95%

TRE

44% - 53%

CORE

Patented rotary random matrix polymer

FILTRATION

MERV 8 - 12

EU 6 - 7

ELECTRICAL

208-240VAC, 25 Amp, 50/60 Hz, Single phase

DIMENSIONS

64 H x 64 W x 42 D (inch); 700 lbs.

1.63 H x 1.63 H x 1.07 D

(meter)

DUCT

4 Round Collars @ 18 Dia (inch)

4 Round Collars @ 458 Dia

(mm)

MAINTENANCE

Yearly filter service

–

light maintenance

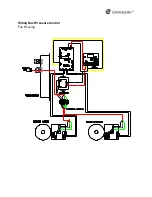

STATION

1 outside

supply

2 inside

supply

3 inside

exhaust

4 outside

exhaust

Temperature [C]

34.7

26.0

24.0

32.6

Relative Humidity

[%]

50.3

62.5

49.5

43.9

SRE: 70% TRE: 53% LPC: 0.43 ASE: 85%

Temperature [C]

0.0

20.3

22.0

4.8

Relative Humidity

[%]

75.3

37.8

39.4

76.5

SRE: 83% TRE: 79% LPC: 0.69 ASE: 96%

SRE: Sensible recovery effectiveness

TRE: Total recovery effectiveness

LPC: Latent performance coefficient

ASE: Apparent sensible effectiveness