Version 1

29

Locating faulty valves

Utilizing the contact (stethoscope) module in the Ultraprobe, valves can easily be monitored to

determine if a valve is operating properly. As a liquid or gas flows through a pipe, there is little or no

turbulence generated except at bends or obstacles. In the case of a leaking valve, the escaping

liquid or gas will move from a high to a low pressure area, creating turbulence on the low pressure

or "down-stream" side. This produces a white noise. The ultrasonic component of this "white noise"

is much stronger than the audible component. If a valve is leaking internally, the ultrasonic

emissions generated at the orifice site will be heard and noted on the meter. The sounds of a

leaking valve seat will vary depending upon the density of the liquid or gas. In some instances it will

be heard as a subtle

crackling sound, at other times as a loud rushing sound. Sound quality

depends on fluid viscosity and internal pipe pressure differentials.

As an ex-ample, water flowing under low to mid pressures may be easily recognized as water.

However, water under high pressure rushing through a partially open valve may sound very much

like steam. To discriminate: reduce the sensitivity, touch a steam line and listen to the sound

quality, then touch a water line. Once you have become familiar with the sound differences,

continue your inspection.

A properly seated valve will generate no sound. In some high pressure situations, the ultrasound

generated within the system will be so intense that surface waves will travel from other valves or

parts of the system and make it difficult to diagnose valve leakage. In this case it is still possible to

diagnose valve blow-through by comparing sonic intensity differences by reducing the sensitivity

and touching just upstream of the valve, at the valve seat and just downstream of the valve.

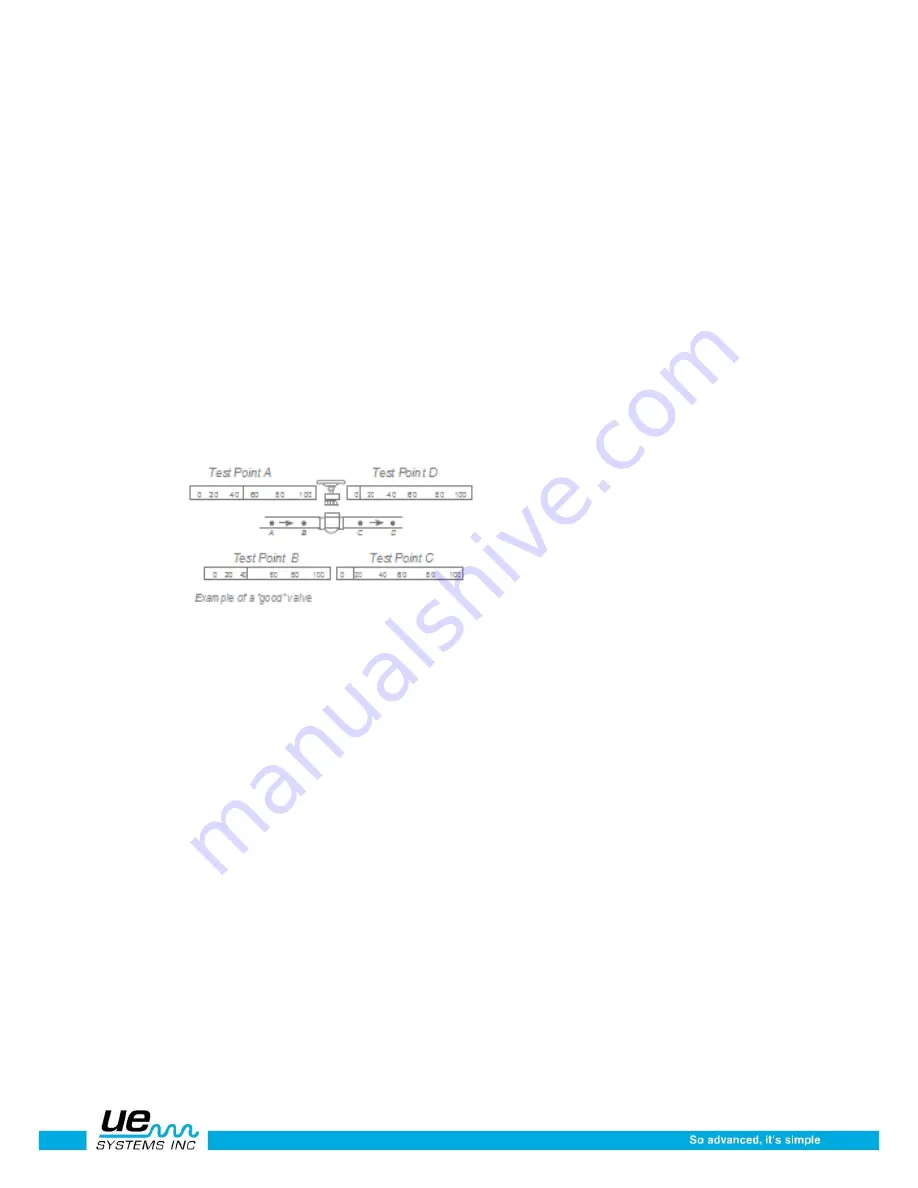

Procedure for valve check

1. Use stethoscope module.

2. Touch downstream side of valve and listen through headset.

3. When necessary, if there is too much sound, reduce sensitivity.

4. For comparative readings, usually in high pres-sure systems:

a. Touch upstream side and reduce sensitivity to minimize any sound (usually bring the

meter to a mid-line "50 %" reading).

b. Touch valve seat and/or downstream side.

Compare sonic differentials. If the valve is leaking, the sound level on the seat or down-

stream side will be equal to or louder than the upstream side.