Usage

12

2.0

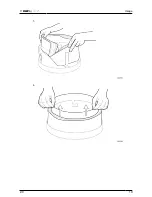

1. Raise the dust cylinder package from the transport position by lifting with the

lifting handles, see Figure 3-1, page

8

, according to Figure 4-1, page

12

.

Figure 4-1. Raising the dust cylinder package

2. Lift until the catches Figure 4-2, page

12

fasten firmly in the top lug on the

chassis for operating position.

Figure 4-2. Locking the dust cylinder package

3. Make sure that both catches are properly located in the lugs.

7\UROLW9&('