TFP1253

Page 6 of 8

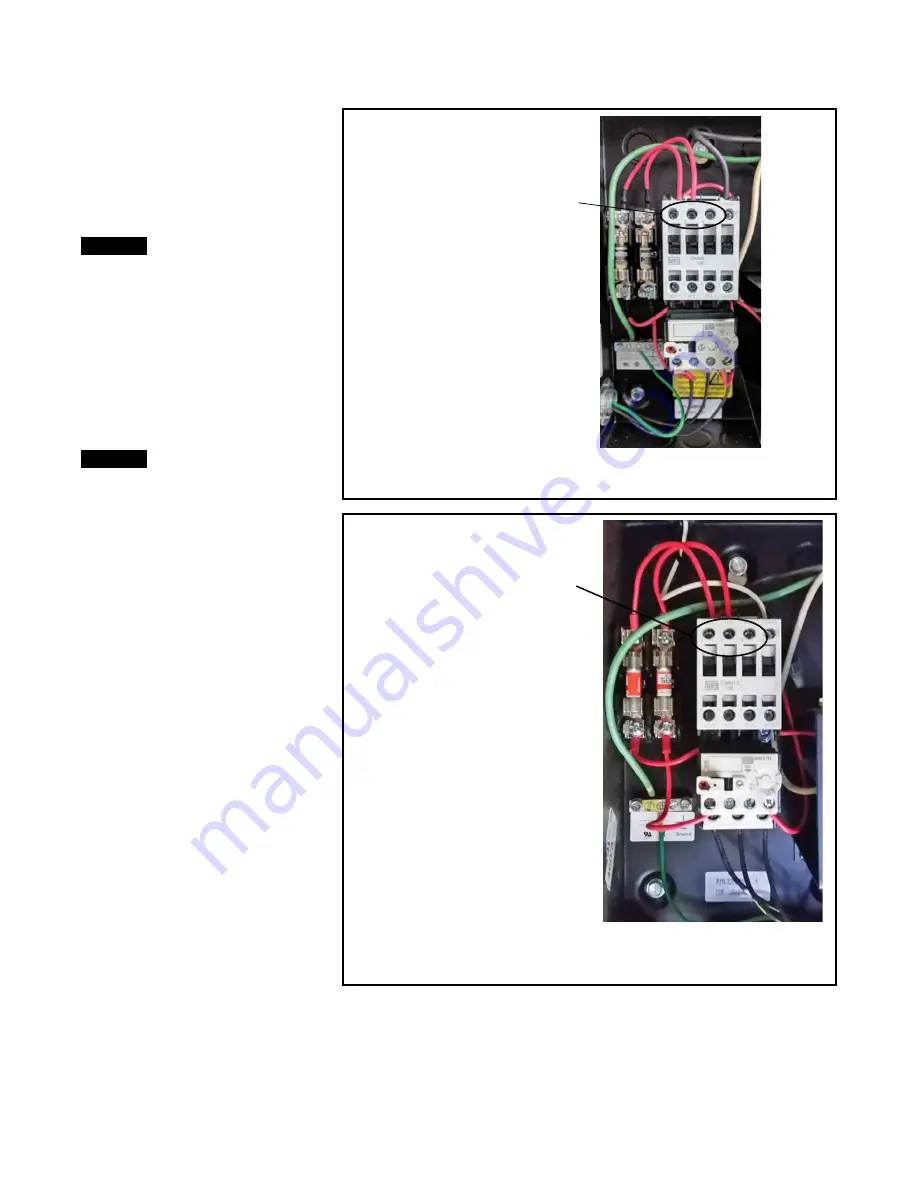

460 VAC/3 PHASE/60 HZ OR

208 VAC/3 PHASE 60 HZ CONNECTIONS

LANDING POINTS

LABELED L1, L2, L3

The air compressors come with pre-

punched holes in the feet for easy

mounting to the floor using standard

anchors.

Note:

Vibration pads (supplied) must be

installed under the feet of the air compressor

to ensure warranty of the air compressor.

Step 2. Power Supply

NOTICE

It is recommended that a service dis-

connect be provided adjacent to the air

compressor.

The air compressors require a dedi-

cated power supply that is terminated

in the power supply box on the air com-

pressor as shown in Figure 3A, 3B, or

3C as applicable. Verify the voltage

of the power supply available for the

air compressor is compatible with

the voltage requirements of the air

compressor.

NOTICE

With the TNGC-1500/2000 and the

TNGC-3000, verify that the compres-

sor and motor starter are configured

for operating at 208 VAC/3 phase

when providing 208 VAC/3 phase to

the control box.

Step 3: Plumb the Air Supply Line

For compressors in the Americas, the

air discharge plumbing from the air

compressor is to be connected to the

inlet of the nitrogen generator using

1/2 in. black steel, galvanized steel or

copper lines. For compressors in EMEA

and APAC, the air discharge plumb-

ing should first be connected to the

WSD-25 water separator which then is

to be connected to the inlet of the nitro-

gen generator.

Step 4: Plumb the Condensate

Drain Line

The TYCO oil-less air compressor will

discharge condensate water from the

air receiver tank. It is recommended

that the 1/4 in. drain connection be

plumbed to a floor drain or building

exterior. When plumbing to a drain is

not feasible an evaporative collection

chamber can be used.

Note:

Ensure that the receiver tank auto-

drain is connected to an un-switched power

source: 120 VAC for Americas, 230 VAC for

EMEA and APAC.

Note:

The Low Oil Level Sensor on the air

compressor automatically shuts down air

compressor until the proper oil level has

been restored.

Care and

Maintenance

Nitrogen Generators

The TYCO NG-1 1150, NG-1 1500, NG-1

2000, and NG-1 3000 Stand-Alone

Nitrogen Generators, the TNGC-1150

Air Compressor, and TNGC-1500/2000

and 3000 Air Compressors must be

maintained and serviced in accordance

with this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

460 VAC/THREE PHASE/60 HZ OR

208 VAC/THREE PHASE/60 HZ

CONNECTIONS

LABELED L1, L2, L3

FIGURE 3A

MODEL TNGC-1150 AIR COMPRESSOR

AMERICAS POWER SUPPLY CONNECTIONS

FIGURE 3B

MODEL TNGC-1500/2000/3000 AIR COMPRESSOR

AMERICAS POWER SUPPLY CONNECTIONS