TW-SP245 MANUAL

state: 14.03.2019

page

5

of

12

3.3 Unpacking & Check

When open the packing, please make sure to use the proper tools, wear protective cloth,

gloves, safety helmet

Make sure that the product and parts in box should be complete and identical with the part

list. If not, please contact with the manufacturer in time.

4. Maintenance

Maintenance should be acted before daily working every day.

Clean the outside of the press with dry, clean and soft cloth and periodically lubricate the

hoist, wheel shaft assembly, the joints and all moving parts with a light oil in normal service.

DO NOT allow lubricant to heel block nor frame of shop press.

When not in use, store the press in a dry location with ram and piston fully retracted.

When press efficiency drops, purge away air from the hydraulic system as described

before.

Check the hydraulic oil: remove the oil filler nut (on the top of the reservoir, if the oil is not

adequate, fill with 22

#(

ISO6743

)

hydraulic jack oil as necessary, then replace the oil

filler nut, purge away air from the hydraulic system as described before.

The equipment must not be repaired or changed spare parts by whom without approval

from the certified technical support engineer.

Summary of Contents for TWSP245

Page 1: ......

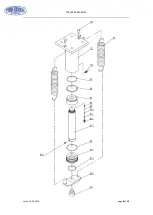

Page 6: ...TW SP245 MANUAL state 14 03 2019 page 6 of 12 5 Spare parts 5 1 Exploded views ...

Page 7: ...TW SP245 MANUAL state 14 03 2019 page 7 of 12 ...

Page 8: ...TW SP245 MANUAL state 14 03 2019 page 8 of 12 ...

Page 11: ...TW SP245 MANUAL state 14 03 2019 page 11 of 12 ...

Page 12: ...TW SP245 MANUAL state 14 03 2019 page 12 of 12 ...