Page 11

Instructions for use

When a BI is removed from its position during incubation

process, an audible alarm will sound to indicate that the

tube should be returned to the corresponding position.

If the indicator is not re-introduced into the reading

position after 10 seconds of being withdrawn, the reading

will be cancelled and the cancelation will be informed

through the printing of a ticket.

Cancellation of a reading

The incubator contains an internal temperature control.

If the temperature falls outside of the specified range

(37±2) ºC or (60±2) ºC, the blue temperature led light will

start to twinkle.

Temperature can be externally monitored by using a

thermometer. The auto-reader has a special hole for

placing the thermometer which is located at the right

side of the device.

Temperature monitoring

Care and cleaning

Replacement of the paper roll

Thermal paper specifications

Recommended paper: JUJO AF50KSE3 or similar.

Paper width : 58 mm

Maximum paper thickness: 60 g/m2

Maximum diameter size: 23 mm

The printer uses thermal paper rolls.

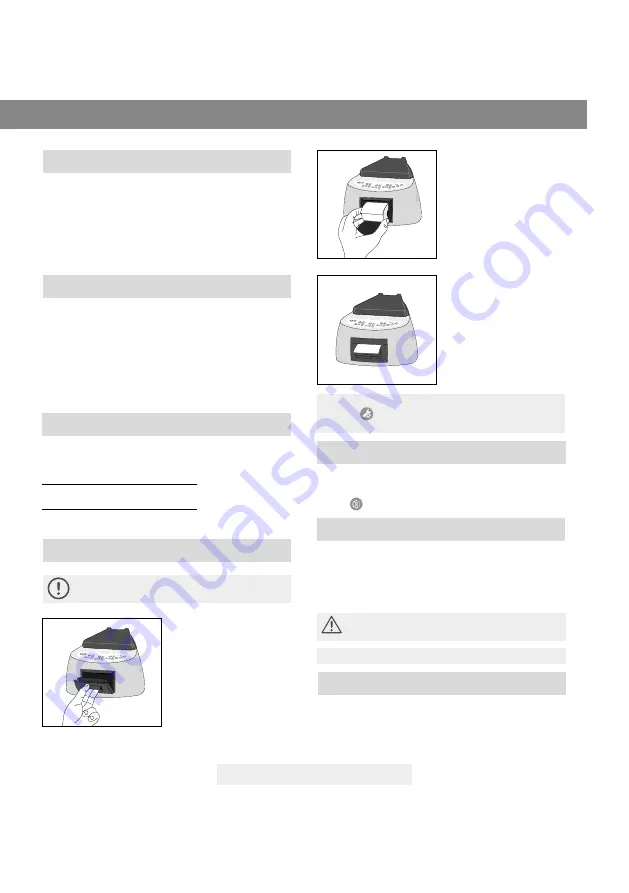

1. To replace the paper

roll, pull the handle of

the printer’s door. Open

the printer’s cover and

remove the spent roll.

2. Place the new paper roll

with the outer side up.

3. Close the printer cover

by pressing on the sides

of the lid.

NOTE:

You can check the correct paper replacement by

pressing

, this button will force the advance of the

paper a few centimeters.

The incubator allows reprinting of the last 3 results by

fluorescence readout. For printing the results, press the

button

for 3 seconds.

Reprinting of results

Clean the outer surface of the incubator with a damp

cloth moistened with a small amount of detergent. Do

not clean interior components. If additional cleaning of

the internal components of the equipment is required,

contact your distributor or manufacturer.

Always unplug the auto-reader and allow it to cool

before cleaning. Do not immerse the unit in liquid.

NOTA:

The auto-reader does not need routine maintenance.

The auto-reader allows updating the firmware periodically

(program that controls the device and defines its different

features) through the use of a firmware update utility.

This software verifies, by using the internet, the latest

Firmware update