Maintenance

55

Important!

All maintenance work labelled with the adjacent symbol may only be performed by qualified

personnel.

The maintenance for the combustion engine is not listed here. Please refer to the accompanying

operating manual of the combustion engine.

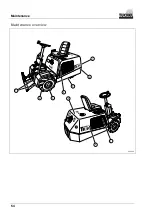

10-hour maintenance / daily

Check point

Maintenance work

Pos.

Page

Air filter

Cleaning.

Replace immediately if the lamp in the display panel lights up.

See operating manual of the combustion engine.

–

–

Hydraulic oil

Check oil fill level.

2

61

Hydraulic tank

Visual inspection / leak-tightness check

Repair by specialist repair shop only.

–

–

Hydraulic hose line

Hydraulic connections

Fuel tank

Tyres

Visual inspection for damage.

Check profile depth and air pressure.

6

59

Wheel nuts

Check daily during the first week. Thereafter, check for

tightness every 50 operating hours and retighten if necessary.

5

60

Engine bonnet, steps,

mounting bolts

Check for tightness and retighten if necessary.

–

–

Wheel house, mounting

bolts

Wheel house/step,

accelerator pedal,

operating levers

For heavy soiling, clean in-between the operation.

–

–

Radiator for engine coolant

(radiator cooling fins)

Free the fins of dirt.

–

58

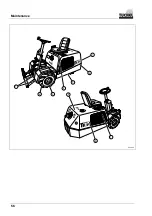

50-hour maintenance / weekly

►

Interval: Type A

Check point

Maintenance work

Pos.

Page

Hydraulic filter

First replacement after 50 operating hours, thereafter every

250 operating hours.

8

62

Hydraulic oil

First replacement after 50 operating hours, thereafter every

1000 operating hours. Check oil fill level after test run.

2

63

Steering cylinder and

steering knuckle

Grease each lubricating point front and rear.

1

60

Lower link

Grease the two lubricating points.

7

60

Tyres

For heavy soiling, clean immediately after the operation.

–

–

Wheel nuts

Check for tightness and retighten if necessary.

5

60

Engine bonnet, filler necks

For heavy soiling, clean immediately after the operation.

–

–