5

by specific load and installation conditions. Also, install a mechanical

stopper within the stroke range in case of emergency.

4. Operation

1.

Be sure that the dynamic or static load carried or sustained by jack does not exceed its capacity.

2.

Make sure that the surface temperature of the housing does not exceed temperature of -15ºC to 80ºC

during operation. If using a traveling nut type unit, measure the traveling nut surface temperature.

3.

The maximum input speed is 1800 rpm as long as the input power dose not exceed the unit’s maximum

allowable input power.

4.

Do not operate continuously. Maximum allowable input power ratings are based on a 20% duty cycle per

30 minutes for the JWM (Machine Screw Type) and 30% for the JWB (Ball Screw Type) and JWH (High

Lead Ball Screw Type). Duty cycle (%) per 30 min. can be calculated using the following formula: (30min.

- off time per cycle) / 30 X 100. For operation longer than that mentioned above or for any continuous

operation, the jacks temperature must be monitored and should not exceed 80ºC max. in order to

determine its duty cycle.

5.

Be sure that starting torque is 200% or more of required running torque.

6.

Be sure that ample driving power is available to drive the jack when using in temperatures below 0ºC.

Low temperatures decrease the jack’s efficiency due to the increased grease viscosity inside the gear

box.

7.

Although JWM has self-locking feature, vibration and shock may affect its efficiency, in which case a

brake unit is required. JWB and JWH must have brake units that over power their holding torque because

of their extremely high efficiencies.

8.

Never approach or touch the rotary parts (input shaft, etc.) or the screw during operation.

5. Maintenance and inspection

1. The jack is shipped prepacked with grease. Recommended grease brands are shown in Table 3. Under

normal operation, lubrication is required every 6 months, however, this interval may vary as frequency of

use and conditions change. Severe operating conditions will require a self-lubricating system. See Table

4 for the lubrication cycle.

※

In case of the made-to order type, confirm with the final drawing, used grease might not be same as

standard.

2. When lubricating the screw, use a brush to spread the grease on the screw after the old grease has been

removed. See Table 5 for the amount of grease to be applied.

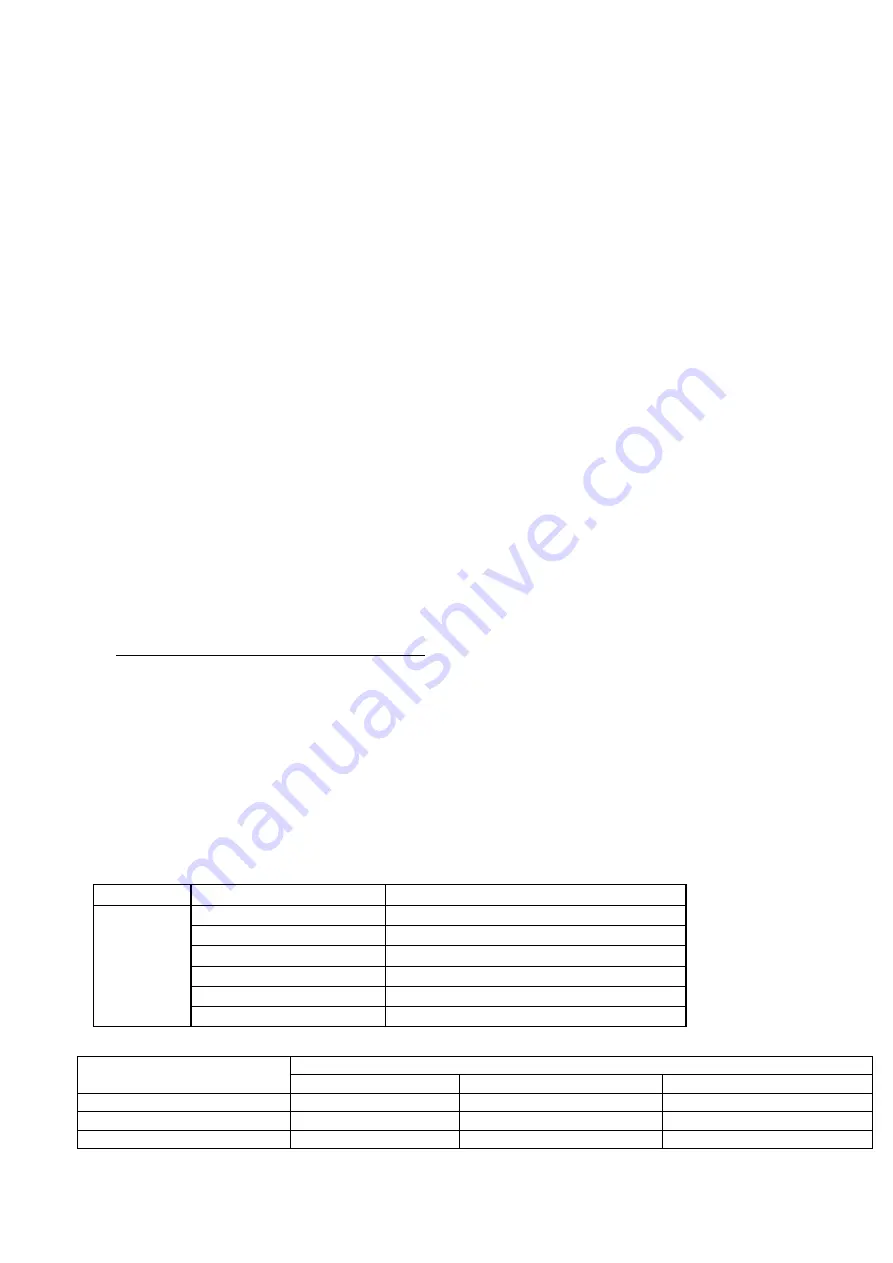

Jack operating cycle

Lubricating Cycle

Machine screw

Ball screw

Gear housing

50 to 100 times / day

1 month

3 months

3 months

10 to 50 times / day

3 month

3 to 6 months

3 to 6 months

1 to 10

times / day

6 mo.s to 1 yr.

6 mo.s to 1 yr.

6 mo.s to 1 yr.

Part

Maker

Grease

Shaft

Reducer

Unit

Tsubakimoto Chain

JWGS

Idemitsu Kosan

※

Daphne Eponex Grease SR No.1

Nippon Grease

Niglube EP-1K

Exson Mobile

Mobilux EP No.1

Cosmo Lubricants

Cosmo Grease Dynamax EP No.1

Showa Shell

Shell Alvania EP Grease 1

Table 3. Recommended Grease

※

Daphne Eponex

is prepacked.

Note: JWGS100G is

available in 100g tube.

Table 4. Lubrication Intervals

★