1: Introduction

4

Table 1. Certifier

®

FA Test System Parts List

Item

no.

Description

Part

no.

Qty

High Flow standard kit (part no. 4070)

1

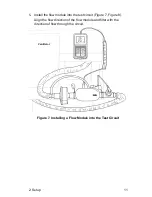

Controller module

4078

1

2

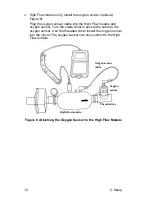

High Flow module

4071

1

3

Bacteria filter, 22-mm x 22-mm

male/female, for use with High Flow

module (single use)

1602341

1

4

Soft carrying case (holds Certifier

®

FA Test

System and accessories)

1319289

1

5

Adapter, 15-mm ID x 22-mm OD

1102093

1

6

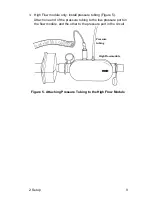

Airway pressure fitting with screen

1611330

1

7

Adapter, 22-mm x 6-mm (for interfacing

High Flow module to Low Flow filter, for

use with oxygen concentrator)

1102091

2

8

Pressure tubing, 1/8-in. ID x 1/4-in. OD x

48-in. length, silicone

3002053

1

9

Mounting bracket (includes mounting

bracket, screws, and Velcro strap)

1040044

1

10

Pocket driver (used to remove/install the

controller module battery cover)

3012034

1

11

AA batteries (not shown)

NA

4

12

Certifier

®

FA Test System Operator’s

Manual (not shown)

1980436

1