saue

5

Series 90

Functional Description

2

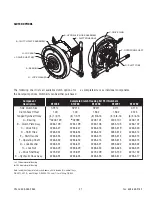

Piston

Roller Bearing

Control Piston

Input Shaft

Valve Plate

Cylinder Block

Cradle Swashplate

Manual Displacement Control

Charge Pump

2. Functional Description

This section describes the operation of pumps, motors, and their various serviceable features. It is a useful

reference for readers unfamiliar with the functioning of a specific system.

2.1

General Description and Cross Sectional Views

90000189

Series 90 Variable Displacement Pump (PV)

Series 90 Fixed Displacement Motor (MF)

90000347

90000346

Series 90 PV Cross Section

2.1.1

Variable Displacement Pumps

The Variable Displacement Pump (PV) is designed to

convert an input torque into hydraulic power. The

input shaft turns the pump cylinder which contains a

ring of pistons. The pistons run against a tilted plate,

called the swashplate. This causes the pistons to

compress the hydraulic fluid which imparts the input

energy into the hydraulic fluid. The high pressure fluid

is then ported out to provide power to a remote

function.

The swashplate angle can be varied by the control

piston. Altering the swashplate angle varies the dis-

placement of fluid in a given revolution of the input

shaft. A larger angle causes greater displacement

which yields greater output torque for a given input. A

smaller angle reduces the displacement per revolu-

tion and yields greater speed for a given input.

2.1.2

Fixed Displacement Motor

The Fixed Displacement Motor (MF) is designed to

convert an input of hydraulic power into an output

torque. It operates in the reverse manner of the

pump. The high pressure hydraulic fluid enters through

the input port. The fluid pressure builds behind the

pistons causing them to move down the swashplate

(the path of least resistance). As the piston returns up

the swashplate again, the fluid is allowed to exit

through the exit port. The spinning pistons are housed

in a cylinder which is connected to the output shaft.

The output torque can be applied to a mechanical

function.

CONTENTS

Summary of Contents for PTV100/72

Page 11: ......

Page 12: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 44: ......

Page 54: ...Contents iv 032015 PN 4 ...

Page 175: ...Troubleshooting 70 35 032015 PN 133 ...

Page 187: ...Troubleshooting 70 47 032015 PN 145 ...

Page 205: ...Warranty DX EMISSIONS EPA 19 12DEC12 2 2 TS1721 UN 15JUL13 90 6 032015 PN 163 ...

Page 213: ...Warranty DX EMISSIONS CARB 19 01AUG14 8 8 RG26036 UN 24JUN14 90 14 032015 PN 171 ...

Page 214: ...Warranty 90 15 032015 PN 172 ...

Page 220: ...Engine Registration IBC 2 032015 PN 178 ...

Page 223: ...Engine Registration IBC 5 032015 PN 181 ...

Page 224: ...Engine Registration IBC 6 032015 PN 182 ...

Page 225: ...SERVICE MANUAL ...

Page 262: ...saue Axial Piston Pumps and Motors Service Manual Series 90 CONTENTS ...

Page 348: ...saue 87 Series 90 Exploded View Parts Drawings 10 Notes CONTENTS ...

Page 350: ......

Page 351: ......

Page 352: ......

Page 353: ......

Page 354: ......

Page 355: ......

Page 356: ......

Page 357: ......

Page 358: ......

Page 359: ......

Page 360: ......

Page 361: ......

Page 362: ......

Page 363: ......

Page 364: ......

Page 365: ......

Page 366: ......

Page 367: ......

Page 368: ......

Page 369: ......

Page 370: ......

Page 371: ......

Page 372: ......

Page 373: ......

Page 374: ......

Page 375: ......

Page 376: ......

Page 377: ......

Page 378: ......

Page 379: ......

Page 380: ......

Page 381: ......

Page 382: ......

Page 383: ......

Page 384: ......

Page 385: ......

Page 386: ......

Page 387: ......

Page 388: ......

Page 389: ......

Page 390: ......

Page 391: ......

Page 392: ......

Page 393: ......

Page 394: ......

Page 395: ......

Page 396: ......

Page 397: ......

Page 438: ......

Page 439: ......

Page 440: ......

Page 441: ......