Section 5: Maintenance

21

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove

the key from the keyswitch on units so equipped.

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

1. Stop the engine, wait for all moving

parts to come to a complete stop, discon-

nect the spark plug wire and prevent it

from contacting the spark plug.

2. Remove the hair pin cotters securing

the upper ends of the control rods to the

plastic thumb latches and wheel drive con-

trol levers (see J, Fig. 2-5).

3. Thread the rods in or out of the idler

arm (A, Fig. 5-2) as needed. Adjust each

wheel drive control rod (A, Fig. 5-3) until

there is a 1-1/4" (32mm) gap between the

rod and the plastic thumb latch. Adjust

both control rods evenly.

4. Re-install the hair pin cotters on the

outside of the wheel drive levers.

CUTTER BAR DRIVE BELT

REMOVAL/REPLACEMENT

Replace the cutter bar drive belt if it is

cracked, severely frayed, or worn to the

point where proper tension can no longer

be applied by the spring loaded idler.

1. Stop the engine, wait for all moving

parts to come to a complete stop, discon-

nect the spark plug wire and prevent it

from contacting the spark plug.

2. Put the cutter bar lever in the OFF posi-

tion (Fig. 4-7). Reach up underneath the

unit and remove the belt from the small

lower pulley (Fig. 5-4).

3. Remove screws and washers (B, Fig. 5-

5) and both belt guides (A). Remove the

belt from the large pulley.

4. Install new belt as shown in Fig. 5-4.

5. Reinstall belt guides (A, Fig. 5-5) and

screws and washers (B). Adjust the guides

1/16" - 1/8" (1.6-3.2mm) away from belt.

CUTTER BAR BELT GUIDE

ADJUSTMENT

1. Stop the engine, wait for all moving

parts to come to a complete stop, discon-

nect the spark plug wire and prevent it

from contacting the spark plug.

2. Place the belt under tension (Fig. 4-7)

by moving the cutter bar lever to the ON

position.

3. Adjust front belt guides (Y, Fig. 5-4)

1/16"—1/8" (1.6—3.17 mm) away from

belt.

4. Secure guides.

5. Adjust the right rear belt guide (Z) 1/4"

(6.35 mm) from the belt (Fig. 5-4).

6. Secure the guide.

WHEEL DRIVE BELT

ADJUSTMENT

Poor wheel traction can result if the belt

tension spring (B, Fig. 5-2) has loosened,

or if the wheel drive belt has worn.

To Adjust Wheel Belt Tension:

1. Move the end of spring (B, Fig. 5-2),

located on the underside of the deck, to

the lower hole (C).

2. If the belt tension is still too loose, the

spring or the belt may need replacing.

WHEEL DRIVE BELT

REMOVAL/REPLACEMENT

When a wheel drive belt is frayed, broken

or worn to the point where tension can no

longer be controlled with the idler pulley,

the belt or spring must be replaced.

NOTE: Prop the unit up by placing sturdy

supports under the engine deck.

To Remove the Wheel Drive Belt:

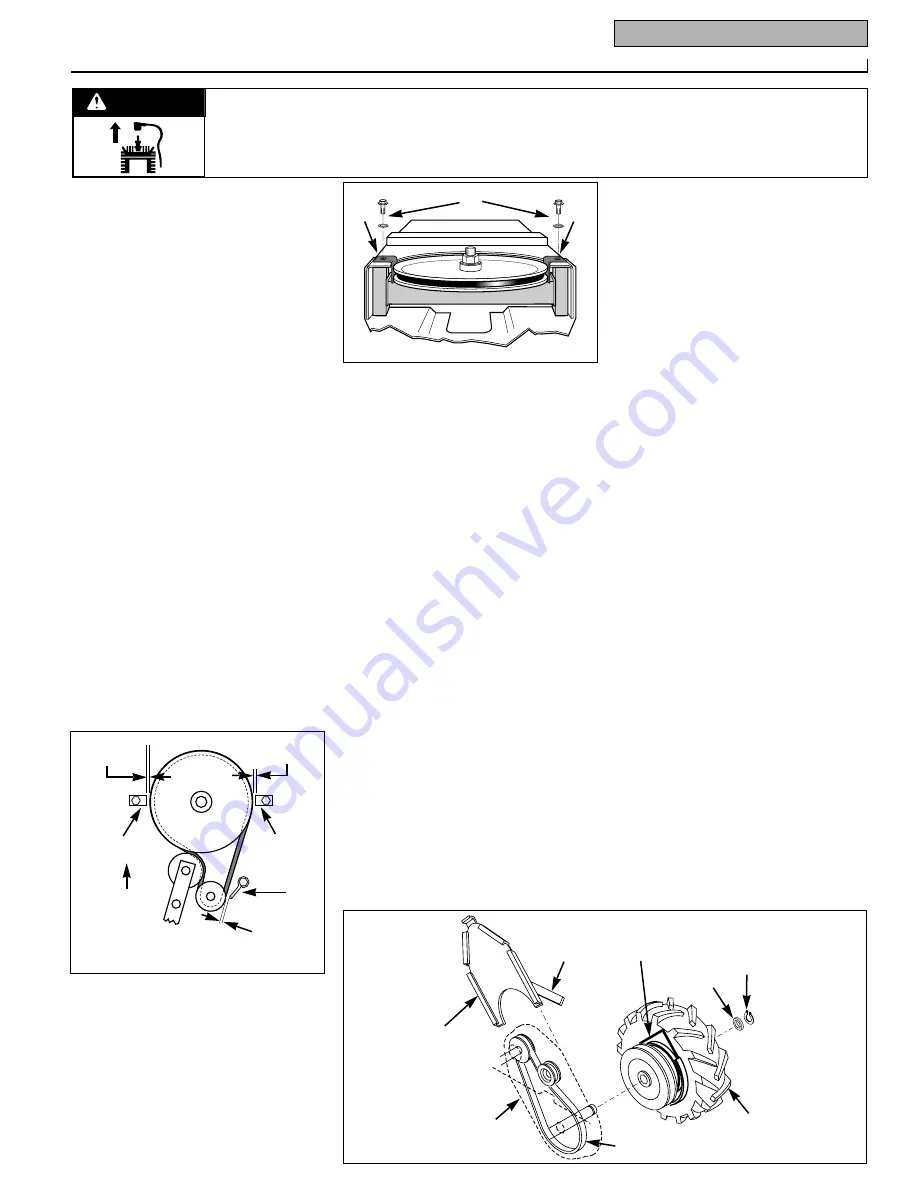

1. Remove drive belt cover (A, Fig. 5-6).

2. Remove snap ring (B) and washer (C)

from drive axle.

3. Remove wheel assembly (F).

4. Slip the drive belt off the pulleys and

off the unit.

To Replace the Wheel Drive Belt:

1. Slide wheel assembly (F, Fig. 5-6) onto

axles. Note that seal tabs (AA) fit inside

the belt guard (J).

2. Route belt (E) into place around pulley

on wheel assembly (F).

3. Secure wheel with washer (C) and snap

ring (B) removed earlier.

4. Install drive belt cover assembly (A).

Note that finger (H) on drive belt cover

points toward the front of the unit.

WHEEL DRIVE BELT GUIDE

ADJUSTMENT

1. Place belt under tension by engaging

wheel drive clutch lever. See Fig. 4-5.

2. Remove Drive Belt Cover (A, Fig. 5-6).

3. Adjust belt guide (A, Fig. 5-7) to 1/16”

(1.6mm) or less away from belt.

4. Adjust belt guide (B) 1/4” (6.4mm)

away from pulley (D).

5. Tighten belt guide (B) at bolt (C) after

adjusting.

6. Install belt cover (A, Fig. 5-6).

A

A

B

Fig. 5-5

A

H

J

E

F

C

B

AA

Fig. 5-6

1/16"-1/8"

(1.6-3.2mm)

1/4"

(6.4mm)

FRONT

Fig. 5-4

Y

Y

Z

1/16"-1/8"

(1.6-3.2mm)