TX6356 User Manual

TX6356-UM-EN-01 27

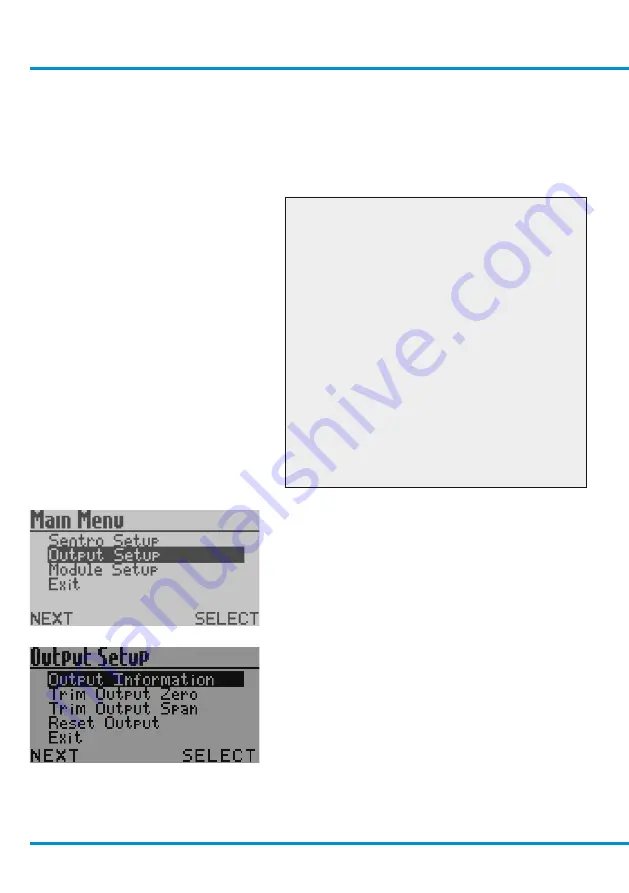

4.5.2 Output Setup

This enables you to view information on and

setup characteristics of the

Sentro Humidity

Sensor

output signal.

Checkpoint

The output signal type of the

Sentro

Humidity Sensor

is configured during

manufacture. The output signal will be one

of five types:

•

0.4 to 2 V analogue output signal

•

4 to 20 mA analogue output signal

•

5 to 15 Hz output

•

Dual relay contacts

•

RS485 digital output signal

Each of the five signal types has a unique

set of menus that enable you to view and

configure characteristics of the output

signal. All five sets of menus are described

in the following sections.

From the

Main Menu

press

L

, navigate to

Output Setup

and press

R

to enter the

Output Setup Menu

.

4.5.2.1 0.4 to 2 V Analogue Output Signal

The available menus are as follows:

•

Output Information

•

Trim Output Zero

•

Trim Output Span

•

Reset Output

•

Exit

www.trolex.com

Summary of Contents for TX6356

Page 1: ......

Page 2: ......

Page 6: ...6 TX6356 UM EN 01 1 4 Dimensions www trolex com ...

Page 16: ...16 TX6356 UM EN 01 4 Setup and Calibration 4 1 Controls and Indicators www trolex com ...

Page 17: ...TX6356 User Manual TX6356 UM EN 01 17 www trolex com ...

Page 18: ...18 TX6356 UM EN 01 4 2 Software Menus www trolex com ...

Page 55: ......

Page 56: ......