Monopack 2 Manual V1.04

8

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

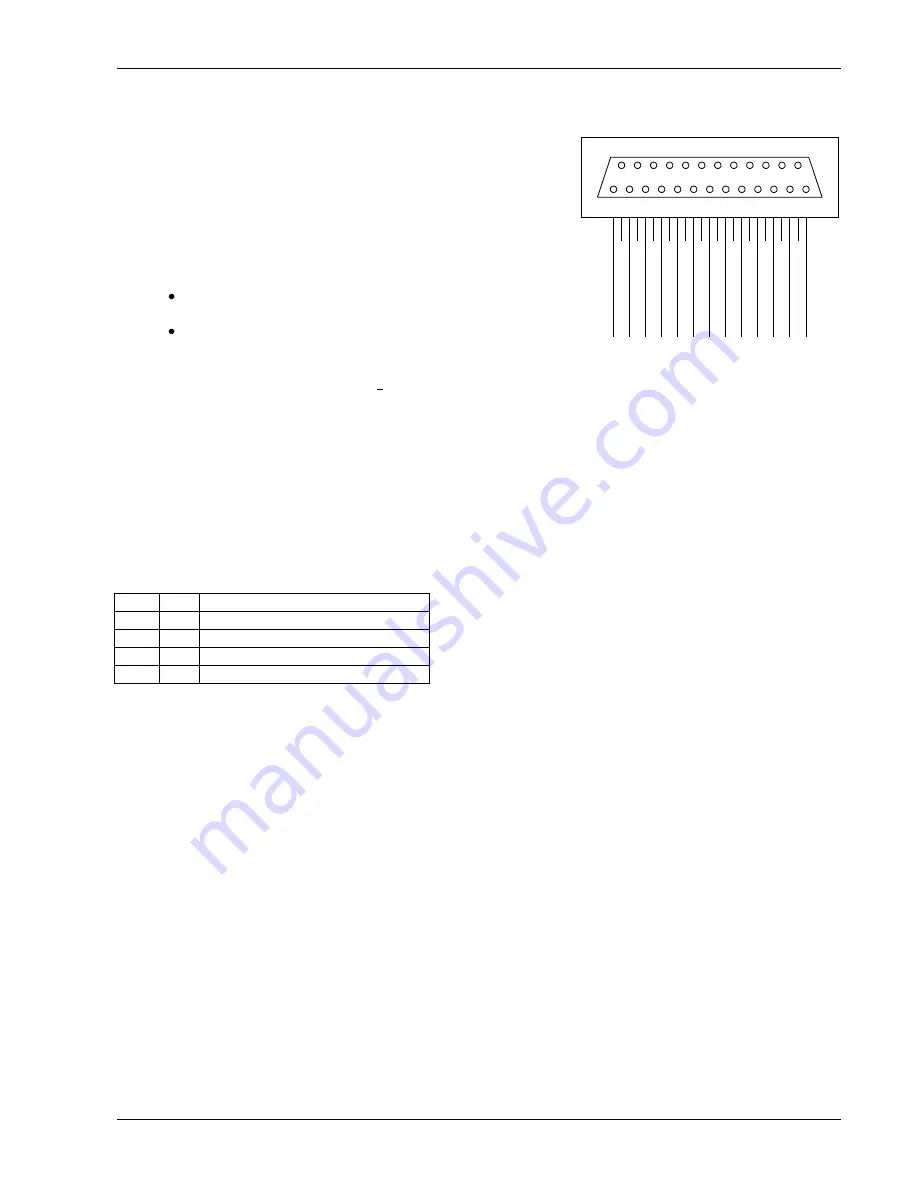

2.7

The 25 pin Sub-D Socket

This socket contains the RS485 interface, the CAN interface, the

STEP/DIRECTION interface and the alarm input and output. The signals

of the incremental encoder input and the stop switch inputs are

output

here as differential signals. The following subsections describe those

interfaces.

2.7.1

CAN and RS485 Interface

For the CAN and the RS485 interface, the same pins are used. So the

interface which shall be used must be selected via the DIP switches:

To use the CAN interface, set switch 1 and 2 to ON and

switch 3 and 4 to OFF position.

To use the RS485 interface, set switch 1 and 2 to OFF and

switch 3 and 4 to ON position.

The termination of both interfaces (120 Ohms) can be switched on and

off with switch 6. Switch 5 is not used.

Attention

: Changing between

RS485 and CAN interface requires a hardware reset (by powering off for

a short time).

2.7.2

The Step/Direction Interface

The Step/Direction interface uses differential signals. After powering on, the Monopack is in Step/Direction mode

so that the Step/Direction interface is usable. After getting the first RS485 or CAN command the Monopack leaves

the Step/Direction mode and enters the command mode where the Step/Direction interface can not be used. It is

possible to switch back to Step/Direction mode by a command.

The motor current control inputs MC0 and MC1 also belong to the Step/Direction interface. Using these inputs, the

motor current can be controlled by hardware in three steps (please see also section 4.2.1):

MC0 MC1 Motor current

0

0

1/3 of configured maximum current

1

0

2/3 of configured maximum current

0

1

2/3 of configured maximum current

1

1

Configured maximum current

In contrast to the old Monopack, these motor current settings can also be controlled by software (please see

section 4.2.1). The step and direction inputs are also provided on the Step/Direction input socket. These are

internally connected to the step/direction inputs of the 25-pin socket.

2.7.3

The Alarm Input

The alarm input is a differential input which can be used to stop the motor in case of emergency. To connect a

key to this input, simply connect it between and +5V (from the incremental encoder connector) and

connect the AlarmIN- input to ground.

2.7.4

The Alarm Output

This differential output is set high in case of an alarm or error condition. Alarm and error conditions can be

cleared by command $74 (s. 4.6.2).

2.7.5

The Incremental Encoder Output

The incremental encoder outputs (EnchA+/-, EnchB+/-, EnchN+/-) provide the encoder signals from the encoder input

(s. 2.4) converted to differential signals.

2.7.6

The Stop Switch Outputs

The stop switch outputs (StopL+/- and StopR+/-) provide the signals from the stop switch inputs (s. 2.3) converted

to differential signals.

1

13

14

25

CA

NL/RS

48

5-

C

A

N

H

/R

S

4

8

5

+

E

nCHB

-

E

n

C

H

B

+

S

top

L-

S

to

p

L

+

A

larmIN-

A

MC1-

M

C

1

+

DIR-

D

IR

+

G

ND

E

nCHN-

E

n

C

H

N

+

E

nCHA

-

E

n

C

H

A

+

S

top

R-

S

to

p

R

+

A

larmO

UT

-

A

larmO

UT

+

MC0-

M

C

0

+

S

T

E

P

-

S

T

E

P

+