Monopack 2 Manual V1.04

20

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.5.3

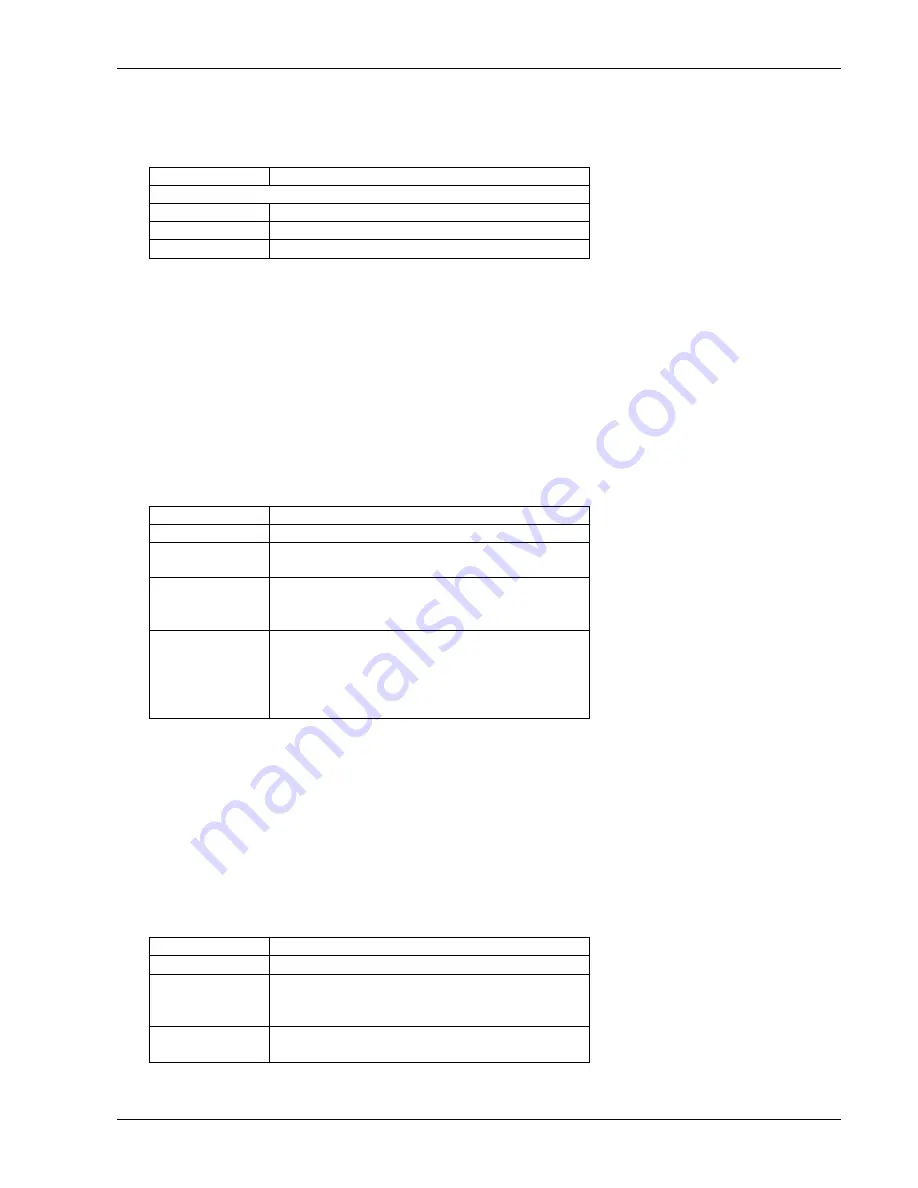

Encoder Counter ($71)

Get the value of the incremental encoder counter register.

CMD

$71

Answer

CMD

$71

P1

0

P2,P3,P4

Encoder counter value (signed 24 bit #)

4.5.4

Encoder Holding Register ($72)

This command has been removed in version 2.09 of the Monopack firmware.

4.5.5

Deviation Alarm ($73)

Enables or disables the deviation alarm. This alarm occurs when the maximum deviation is exceeded. The alarm

output will then be set high. Set the maximum deviation using command $70. The motor can also be stopped

immediately or softly when the alarm occurs. Furthermore, the automatic position correction (see 4.5.6) can be

started n/200 sec (n=1..65535) after a deviation has been detected. In this case, the alarm output will only be set

when the maximum number of retries for automatic position correction has been exceeded. The maximum

deviation has to be set up using command $70 (s. 4.5.1) first. The automatic position correction has to be set up

using command $58 (s. 4.5.6).

CMD

$73

P0

Parameter storage control (s. 4.1)

P1

0: disable deviation alarm

1: enable deviation alarm

P2

0: do not stop when deviation alarm occurs

1: soft stop when deviation alarm occurs

2: hard stop when deviation alarm occurs

P3,P4

0: no automatic position correction after

deviation

1-65535: start automatic position correction n/200

sec after a deviation has been detected (available

since firmware V2.09)

4.5.6

Configure Automatic Position Correction ($58)

Configure if an automatic position correction shall be done at the end of each ramp or when a deviation has been

detected. Automatic position correction can only be used in conjunction with an incremental encoder which has to

be configured correctly first.

When this function is turned on, the Monopack checks if the position counter of the incremental encoder matches

the desired end position at the end of every ramp (since firmware V2.09, the tolerance value defines a tolerance

window around the end position). If this is not the case, the Monopack will try to correct the position of the

motor using the reference search velocity. The maximum number of retries after each ramp can also be configured.

The alarm output will be set high and the position correction will be aborted if this number is exceeded.

This function is an easy to use alternative to the PID controller.

CMD

$58

P0

Parameter storage control (s. 4.1)

P1

0: automatic correction turned off

1-255: maximum number of retries for position

correction after each ramp.

P3,P4

end position tolerance (16 bit unsigned #)

(available since firmware V2.09)