Spectrum Essential Oil Storage System

TRICO CORPORATION

1235 Hickory Street; Pewaukee, WI 53072

For Customer Support: 800-558-7008

P a g e

16 | 20

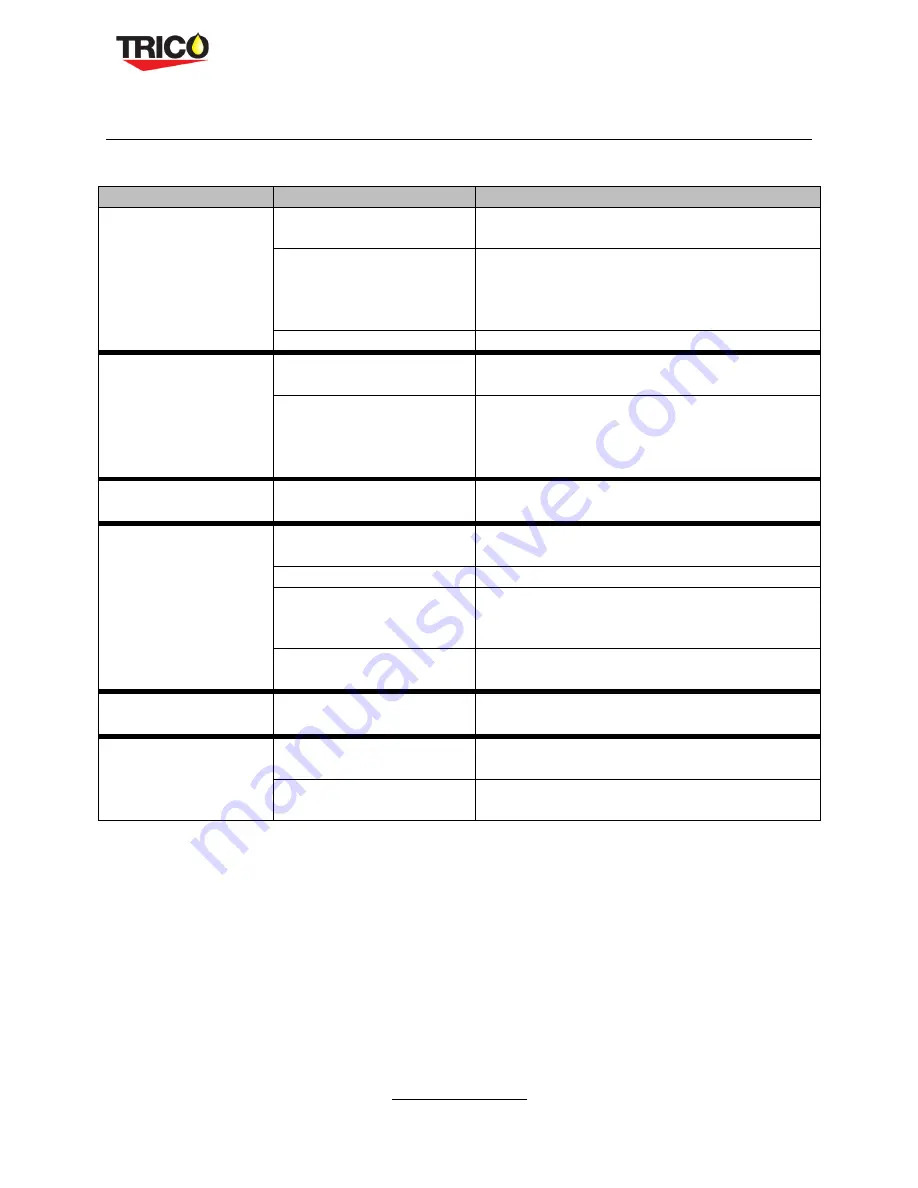

TROUBLESHOOTING

The following troubleshooting guide gives issues, causes, and corrective action. If any of these actions do

not solve the issue entirely, please contact Trico for additional support.

Symptom

Possible Cause(s)

Corrective Action

Pump system does not

prime

Suction wand above liquid

Ensure open end of suction wand remains

completely below surface of liquid

Clogged suction wand

and/or discharge hose line

and/or manifold valves are

closed

Clean suction wand and/or discharge hose line

and/or open manifold valves

Suction wand line too long Reduce length in suction line to reduce pressure

Insufficient flow

Clogged/ kinked discharge

hose line or nozzle

Remove and flush discharge hose line and

nozzle, inspect for damage

Fluid viscosity exceeds

recommended viscosity for

motor

Check viscosity of fluid at temperature. See SUS

vs. Temp. chart or contact fluid supplier. If

viscosity exceeds maximum cSt, fluid must be

warmed to reduce viscosity

Fluid Leaking from

manifold or any fittings

Loose fittings and/or

connections

Check tightness of hose/fitting connections

Electric motor does not

function/ or stops

working

Power On/Off switch not

fully switched

Check On/Off switch

No power to receptacle

Check outlet for power and breaker

Unit has overheated

tripping internal overload

breaker

Turn unit power to the “OFF” position, allow

motor to cool, turn back to “ON” position and

resume filling

Unit generates excessive

heat

Fluid viscosity exceeds maximum recommended

viscosity

Tank is not filling

Tank Manifold Valve is

closed

Open Correct Tank Manifold Valve

Tank is not dispensing

fluid

Tank Shut-Off Valve is

closed

Open Tank Shut-Off Valve below the tank to

have gravity feed for the Dispensing Nozzle

Dispensing Nozzle is

clogged

Clean Dispensing Nozzle to remove

contamination or clogs