49

Step 5. Using only hand pressure, extend the arbor as far to the right as it will go.

Step 6. Using appropriate GO NO-GO gauges, open the funnel and insert gauges into the

indenters to determine the "G" dimensions.

NOTE

Be sure to use gauges corresponding

to proper wire gauge and contact gauge

.

Step 7. If the "G" dimension

is

acceptable, go to Step 14.

If the "G" dimension

is

not acceptable, go to Step 8

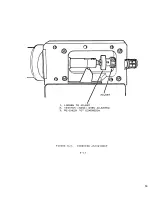

Step 8. Refer to Figure 6-6.

Step 9. Loosen the Stafford clamp collar.

Step 10. Rotate the "ADJUST" adjustable stop counter-clockwise

to decrease the "G" dimension, or clockwise to increase the "G" dimension.

Step 11. Repeat Steps 5 through 10 until the "G" dimension is within acceptable

parameters.

Step 12. Hand-tighten the Stafford clamp collar, being careful not to change the

adjustable stop position.

Step 13. Repeat steps 5 and 6.

NOTE

Operator-adjustable "G" dimension PORTA-TACs should be adjusted at setting 6.

If desired after adjustment has been completed, GO NO-GO verification may be

performed for the remaining settings.

Step 14. Install the crimp cylinder arbor cover plate and the

funnel cover plate removed in Step 3.

Step 15. Connect the air supply to the sleeve valve.

Step 16. Select the magazine with the appropriate contacts and load the magazine onto

the PORTA-TAC.

Step 17. Set the LAST PART Switch to OFF (up) position

Summary of Contents for PORTA TAC E Series

Page 7: ...7 FIGURE 1 1 PORTA TAC CRIMPER FRONT VIEW ...

Page 8: ...8 FIGURE 1 2 PORTA TAC CRIMPER WITH MAGAZINE ...

Page 9: ...9 FIGURE 1 3 PORTA TAC CRIMPER SIDE VIEW ...

Page 11: ...11 ...

Page 17: ...17 ...

Page 26: ...26 FIGURE 4 1 CRIMP CYLINDER ARBOR OPEN ARBOR COVER PLATE REMOVED ...

Page 27: ...27 FIGURE 4 1 CRIMP CYLINDER ARBOR CLOSED ARBOR COVER PLATE REMOVED ...

Page 30: ...30 FIGURE 4 3 CRIMP INSPECTION POINTS ...

Page 31: ...31 FIGURE 4 4 IMPROPER CRIMPS ...

Page 32: ...32 ...

Page 40: ...40 FIGURE 6 1 PANEL COMPONENTS ...

Page 41: ...41 FIGURE 6 2 CABINET COMPONENTS TRANSFER MECHANISM ...

Page 44: ...44 FIGURE 6 3 INDENTER SYSTEM REPLACEMENT ...

Page 45: ...45 ...

Page 46: ...46 FIGURE 6 5 INDENTER REPLACEMENT ...

Page 50: ...50 ...

Page 53: ...53 ...