51

Installazione

Funzionamento

Manutenzione

Unità ad alta precisione Jupiter

Unità a espansione diretta

JDAC / JUAC / JDAV / JUAV / JDWC / JUWC / JDWV / JUWV

Taglie: 0115 – 0125 – 0133 – 0135 – 0150 – 0160

Unità ad acqua refrigerata

JDCC / JUCC / JDCV / JUCV

Taglie: 0020 – 0025 – 0030 – 0040 – 0060

PKG-SVX24B-IT

PROBLEM

POSSIBLE CAUSE

CHECK/CORRECTIVE ACTION

ABSent or LoW Air

FLoW

A) there is no power to the fans.

Check the power supply to the fans

B) The filter is blocked (possible intervention of

the dirty filters alarm).

1) Shake the dust out of the cartridge and clean

with a vacuum cleaner. Replace the filter if it is

completely blocked.

2) Check the correct setting of the dirty filter

pressure switch PFS.

C) Fans rotating in the wrong direction.

reverse input phases and check if fans are

rotating in the correct direction

D) The air flow is obstructed.

Check paragraph “Air DiStriBUtion”

e) the fans’ thermal protection intervenes.

Check the resistance of the fan motor windings.

re-set then measure the voltage and absorption.

F) Fan speed regulator not set correctly.

See paragraph FAn SPeeD ADJUStMent AnD

SPeeD reGULAtor SettinG.

G) excessive head loss in the air distribution

sistem.

1) Check the dimensioning of the air distribution

system, as well as all its parts (ducts, suspended

ceilings, floor plenum, air grilles)

2) (For tDCr and tUCr models - having fans

with backward curved blades) change the power

supply voltage of the fans, in order to increase

the fan rotation speed.

PROBLEM

POSSIBLE CAUSE

CHECK/CORRECTIVE ACTION

interVention oF

one or BotH oF tHe

eLeCtriCAL HeAterS’

SAFetY tHerMoStAtS

A) There is insufficient air flow.

See “LACK oF / ABSent Air FLoW”.

B) the thermostat connection wire is interrupted Check the continuity of the connection of the

safety thermostats to the control system.

C) one or both of the thermostats are broken

replace one or both of the electrical heaters’

safety thermostats

55

53

54

55

53

54

4

52

51

4

52

51

ACCESSORIES

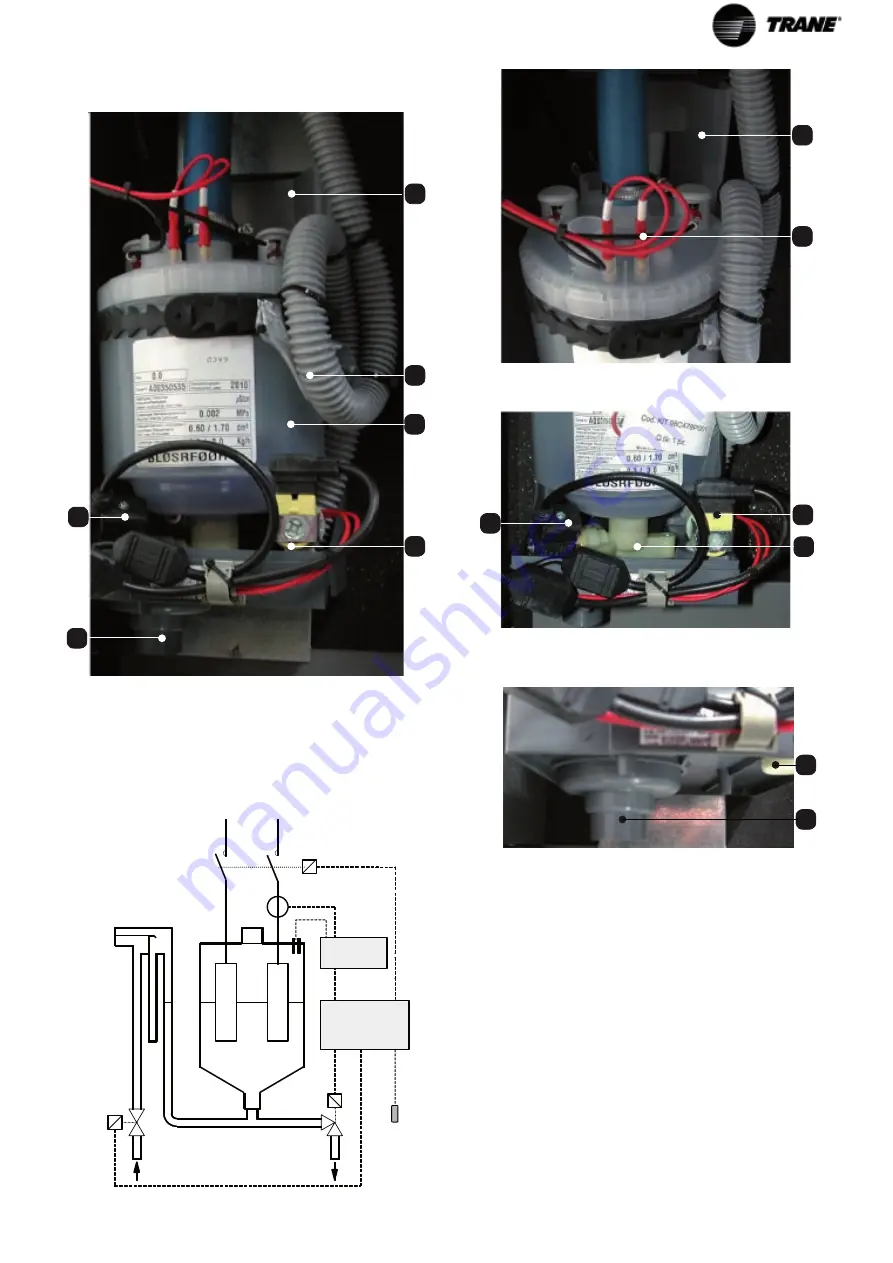

Humidifier

U2

U1

U6

U1 Boiler cylinder

U2 Water supply tray

U3 High water level detector electrodes in the boiler

cylinder

U4 Condenser drain

U5 Collector charge/discharge

U6 Water input

U7 Drain

U8 Feed water solenoid valve

U9 Boiler cylinder electric drainage valve

U10 Overflow pipe (behind the cylinder)

U11 Amperometric transformer for measuring the current

(within the electrical panel)

U12 Humidifier interface board (inside the electrical

panel)

U13 Microprocessor control board

U14 temperature and humidity probe

U9

U9

U8

U3

U2

MANUALE D'USO E MANUTENZIONE

CONDIZIONATORI D'ARIA DI PRECISIONE

(32)

Rev 1.5. – 27-02-2004 IT

32

UMIDIFICATORE

COMPONENTI DEL SISTEMA

Su richiesta l’unità di condizionamento può essere dotata di un umidificatore a elettrodi immersi (versioni D e H). Il gruppo di produzione del

vapore si compone dei seguenti organi.

Fig. 11 a

1.

Scheda di interfaccia umidificatore:

SIU

;

( interna al quandro elettrico ) .

2.

Trasformatore amperometrico per la misura

dell’intensità ( interna al quandro elettrico ).

di corrente assorbita dal cilindro vapore

TAM

;

3.

Vaschetta di carico dell’acqua di alimentazione;

4.

Elettrodi di alto livello dell’acqua nel cilindro

vapore;

5.

Tubo di sfioro del troppo pieno ( DIETRO AL

CILINDRO);

6.

Cilindro ebollitore (o cilindro vapore);

7.

Elettrovalvola dell’acqua di alimentazione:

EVC

;

8.

Elettrovalvola di drenaggio del cilindro ebollitore:

EVS

.

9.

Scheda del controllo a microprocessore:

mP20

;

10.

Sonda di temperatura ed umidità:

STU

;

8

3

4

6

7

U2

U

10

U8

U14

U9

U1

U11

U3

U12

U13

U4

U8

U7

U5

U7