21

Installazione

Funzionamento

Manutenzione

Unità ad alta precisione Jupiter

Unità a espansione diretta

JDAC / JUAC / JDAV / JUAV / JDWC / JUWC / JDWV / JUWV

Taglie: 0115 – 0125 – 0133 – 0135 – 0150 – 0160

Unità ad acqua refrigerata

JDCC / JUCC / JDCV / JUCV

Taglie: 0020 – 0025 – 0030 – 0040 – 0060

PKG-SVX24B-IT

J*AC - J*AV

0151

0251

0331

0351

0501

0601

Recommended minimum size

Model

CAP0251 CAP0251 CAP0331 CAP0361

CAP0511

CAP0661

Max external air temperatur

°C

46

42.5

44.2

43.2

44.5

44.2

J*WC -J*WV

0151

0251

0331

0351

0501

0601

Recommended minimum size

Model

RAL0360 RAL0360 RAL0360 RAL0510

RAL0700

RAL0700

Max external air temperatur

°C

45

45

43

43

45

43

Installation

WARNING! The laying of the lines and the

refrigerant connections must be carried out by

a qualified refrigerant circuit technician.

the refrigeration circuit must be connected to the condensing

unit with copper pipes. the diameter of the pipes must be

chosen according to the length of the refrigerant line itself

(preferably less than 30 m) therefore it is possible that the

internal diameter of the valves supplied by trAne will not

coincide with the diameter of the pipes.

Conforming to the Standards en 14276-1 and en 14276-2

the minimum recommended thickness for the gas supply

pipe where bends are made for the air cooled units with

r410A refrigerant, must be equal to the values present in the

attached table below. the value `r’ refers to the minimum

allowed radius of the bend.

111

I

GB

LINEA DI MANDATA

DISCHARGE LINE

-5

0

5

10

15

20

25

30

35

40

Lunghezza equivalente [m]

3 - Non consentito - Unacceptable

2 - Consentito - Acceptable

1 - Ideale - Recommended

DP/L = 14

DP/L = 12

DP/L = 10

DP/L = 8

DP/L = 7

DP/L = 6

DP/L = 5

DP/L = 4

DP/L = 3

DP/L = 2

DP/L = 1

In conformità alle norme EN14276-1 e EN14276-2 lo spessore minimo

raccomandato per le tubazioni della linea di mandata del gas dove sono

praticate delle curve per le unità condensate ad aria con refrigerante

R410A deve essere pari ai valori presenti nella tabella sotto allegata. I

valori R si riferiscono ai raggi di curvatura minimi consentiti.

Conforming to the S tandards EN14276-1 and EN14276-2 the minimum

recommended thickness for the gas supply pipe where bends are made

for the air cooled units with R410A refrigerant, must be equal to the values

present in the attached table below. The value ‘R’ refers to the minimum

allowed radius of the bend.

Diametro esterno - External Diameter

Raggio di curvatura - Radius of the Bend

Spessore - Thickness

De (mm)

28

100

1,2

22

66

1

18

27

1

16

26

1

12

20

1

De

r

t

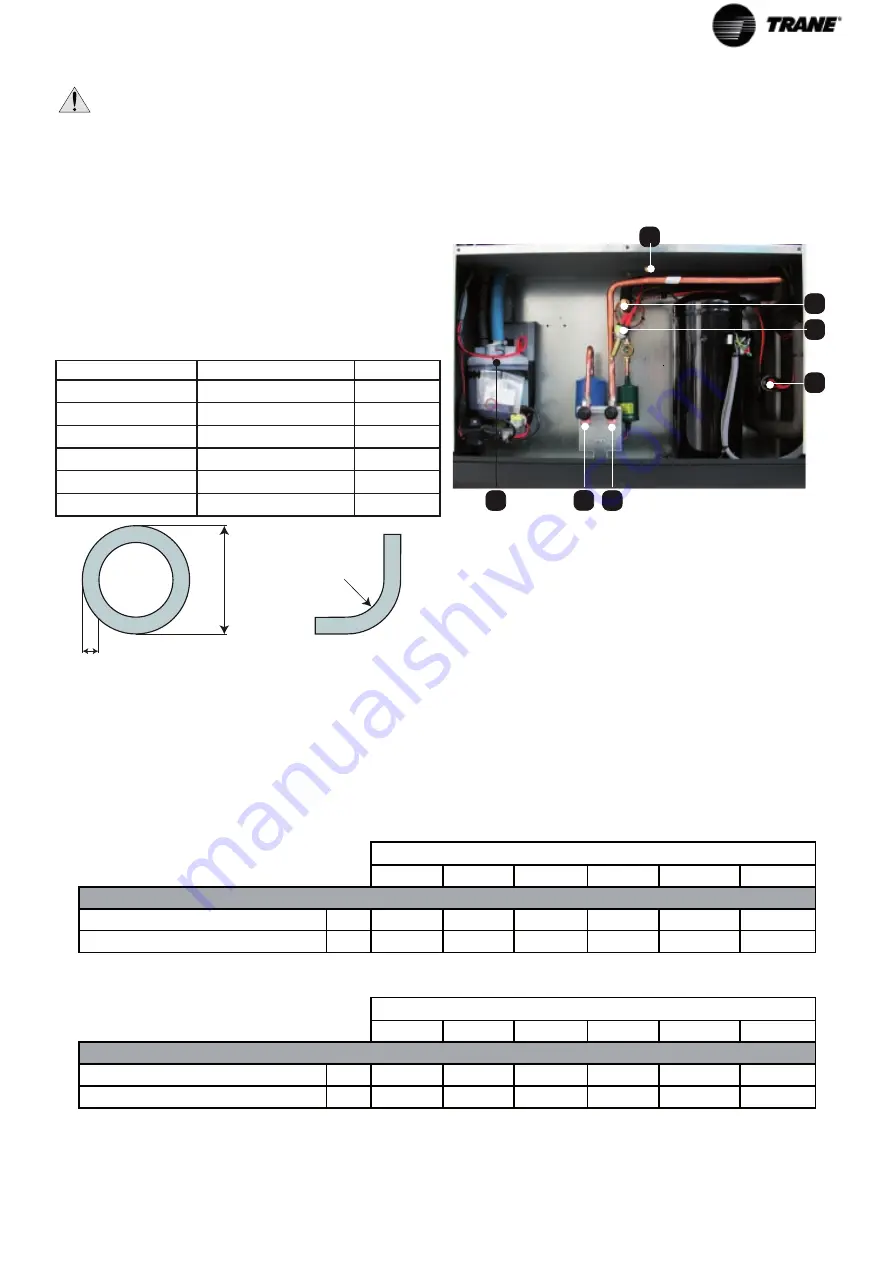

During the installation of the cooling unit, a solenoid

valve should be fitted on the liquid line between the inner

unit and the external condenser, to avoid malfunctioning

and to protect the compressor from unwanted liquid

migration during start- up.

G?

G3

G2

G?

G6

G7

U

to connect the refrigerating circuit to the condensing unit

proceed as follows:

•

check that the diameter of the connections corresponds

to the diameter of the pipes to be connected. if

necessary use suitable copper reductions;

•

weld the piping coming from the condensing unit to the

connections of the air conditioner respecting the inlet

and outlet directions of the refrigerant.

note: with external temperatures of less than -10°C the

use of condensers for low temperatures is recommended:

cap Lt optional.

Remote Dry coolers

External diameter Radius of the bend Thickness

De (mm)

r [mm]

t [mm]

28

100

1,2

22

66

1

18

27

1

16

26

1

12

20

1

Remote air cooled condensers

Recommended minimum size

Recommended minimum size

Model

C°

C°

Model

Max external air temperature

Max external air temperature