42

RLC-SVX023B-GB

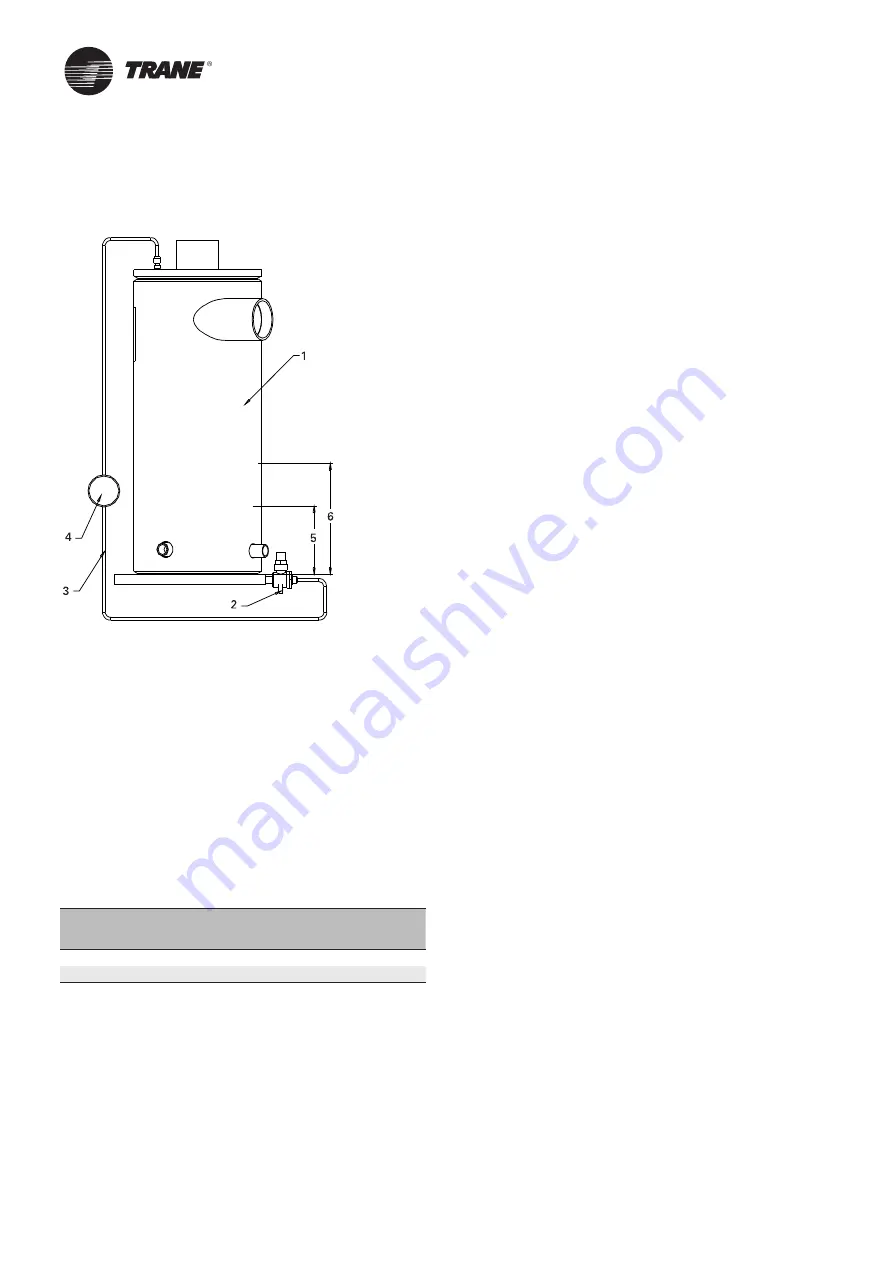

Oil Level Check

Figure 9 –

Determining oil level in the oil separator

1 = Oil separator

2 = Valve

3 = 1/4” refrigeration hose

4 = Sight glass

5 = Minimum oil level

6 = Maximum oil level

How to measure the

oil level

:

1.

Use the oil drain valve (bottom side) and the service valve on the oil separator (top side). This measurement can

be made, when the circuit is not running. Note: the bottom plate of the oil separator is approximately 25mm

thick.

2. The initial oil charge should be approximately at the level in of the above chart. This is the approximate oil level if

all the oil is in the oil lines, fi lter, and oil sump, and the unit is in vacuum so that there is no refrigerant dissolved

in the oil.

After the unit has run for a while, the oil level in the sump can vary greatly. However, if the unit has run ‘normal’

conditions for a long time, the minimum and maximum oil levels should correspond to values shown in below table.

However excessive oil in the system will deteriorate the evaporator approach temperature.

Oil

separator

size

Compressors type

Min. oil

level (mm)

Max. oil

level (mm)

8”

“M” type

50 mm

180 mm

10”

“N” type

50 mm

140 mm

The fi eld charging procedure depends on the circumstances that resulted in the need for oil charge.

1.

Some services procedures may result in loss of small quantities of oil that must be replaced (oil analysis,

compressor fi lter replacement, re-tubing the evaporator, and so forth).

2. Additionally, some maintenance procedures may result in virtually all the oil being removed (compressor motor

burn or total removal of the charge to trouble shoot a unit).

3. Finally, leaks may result in a loss of oil that must be replaced.

Oil charging data.

The oil quantity is written on the nameplate of the unit.

Maintenance Procedures