16

18-CD21D1-12

Installer’s Guide

TABLE 8

π

(D*)

2

4

=

X 7

8. Where long periods of airflow are desired for com-

fort, use long fan cycles instead of continuous air-

flow.

9. Apply other good venting practices as stated in

the venting section of the National Fuel Gas Code

ANSI Z223.1 “latest edition”.

10.

Vent connectors serving appliance vented by

natural draft or non-positive pressure shall

not be connected into any portion of a mech-

anized draft system operating under positive

pressure.

11. Horizontal pipe runs must be supported by hang-

ers, straps or other suitable material in intervals

at a minimum of every 3 feet of pipe.

12. A furnace shall not be connected to a chimney or

flue serving a separate appliance designed to burn

solid fuel.

13. The flow area of the largest section of vertical

vent or chimney shall not exceed 7 times the small-

est listed appliance categorized vent area, flue col-

lar area, or draft hood outlet area unless designed

in accordance with approved engineering methods.

Maximum Vent or Tile

Lined Chimney Flow Area

*Drafthood outlet diameter, flue collar diameter, or listed appliance cat-

egorized vent diameter.

GAS VENT TERMINATION

ROOF PITCH

MINIMUM HEIGHT

FLAT TO 7/12

OVER 7/12 TO 8/12

OVER 8/12 TO 9/12

OVER 9/12 TO 10/12

OVER 10/12 TO 11/12

OVER 11/12 TO 12/12

OVER 12/12 TO 14/12

OVER 14/12 TO 16/12

OVER 16/12 TO 18/12

OVER 18/12 TO 20/12

OVER 20/12 TO 22/12

1.0 FEET *

1.5 FEET

2.0 FEET

2.5 FEET

3.25 FEET

4.0 FEET

5.0 FEET

6.0 FEET

7.0 FEET

7.5 FEET

8.0 FEET

* THIS REQUIREMENT COVERS MOST INSTALLATIONS

d

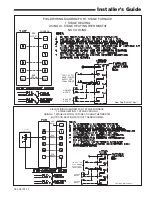

ELECTRICAL CONNECTIONS

▲

WARNING

!

The cabinet must have an uninterrupted or unbroken

ground according to National Electrical Code, ANSI/

NFPA 70 – “latest edition” and Canadian Electrical

Code, CSA C22.1 or local codes to minimize personal

injury if an electrical fault should occur.

Failure to follow this warning could result in an electri-

cal shock, fire, injury, or death.

▲

CAUTION

!

The integrated furnace control is polarity sensitive. The

hot leg of the 115 VAC power must be connected to the

BLACK field lead.

▲

WARNING

!

To prevent injury or death due to electrical shock or

contact with moving parts, lock unit disconnect switch

in the open position before servicing the unit.

Failure to follow this warning could result in electrical

shock, personal injury, or death.

Make wiring connections to the unit as indicated on

enclosed wiring diagram. As with all gas appliances

using electrical power, this furnace shall be connected

into a permanently live electric circuit. It is recom-

mended that it be provided with a separate “circuit

protection device” electric circuit. The furnace must be

electrically grounded in accordance with local codes or

in the absence of local codes with the National Electri-

cal Code, ANSI/NFPA 70 “latest edition” or Canadian

Electrical Code, CSA C22.1, if an external electrical

source is utilized.

All field supplied wiring must conform with the tem-

perature limitation for Type T wire [63° F. (35° C)],

when installed in accordance with these instructions

and wiring diagrams supplied with the furnace. A dis-

connecting means must be located within sight from,

and readily accessible to, the furnace.

Refer to the SERVICE FACTS literature for unit wir-

ing diagrams in addition to the diagram inside the

blower door.