Page 19

Installer’s Guide

Starting the Unit in Cooling Mode

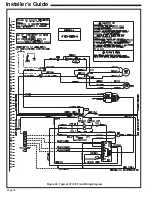

Control Wiring (Class II)

Low voltage control wiring should not be run in conduit with power

wiring unless Class 1 wire of proper voltage rating is used. Route

the thermostat cable or equivalent single leads of No. 18 AWG

colored wire from the thermostat subbase terminals through the

rubber grommet on the unit. See Figures 2, 4, 6, or 8

for the

control entry (24V Entry) location. Make connections as shown

on the unit wiring diagram.

Do not short thermostat wires since this will damage the control

transformer.

Refer to Table 2 for recommended wire sizes and lengths for install-

ing the unit thermostat. The total resistance of these low voltage

wires must not exceed one (1) ohm. Any resistance in excess of 1

ohm may cause the control to malfunction because of the exces-

sive voltage drop.

IMPORTANT:

Upon completion of wiring, check all electrical con-

nections, including factory wiring within the unit.

Make sure all connections are tight. Replace and secure all electri-

cal box covers and access panels before leaving the unit or turning

on the power to the unit.

Pre-Start Quick Checklist

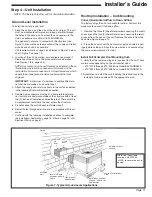

Is the unit properly located and level with the proper

clearance? See Figures 1 to 6. See Step 3-Review

Location and Recommendation Information on page 10.

Is the duct work correctly sized, run, taped, insulated, and

weatherproofed with proper unit arrangement? See

Ductwork Installation section on page 16.

Is the condensate line properly sized, run, trapped, and

pitched? See Condensate Drain Piping section on page

16.

Is the filter of the correct size and quantity? Is it clean and in

place? See Air Filter Installation section on page 16.

Is the wiring properly sized and run according to the unit

wiring diagram? See Electrical Wiring section on page 17.

Are all the wiring connections, including those in the unit,

tight? See Electrical Wiring section on page 17.

Has the unit been properly grounded and fused with the

recommended fuse size? See Electrical Wiring section on

page 17.

Is the thermostat well located, level, and correctly wired?

See Electrical Wiring section on page 17.

Have the air conditioning systems been checked at the service

ports for charge and leak tested if necessary?

Step 5—Unit Startup

Table 2. Thermostat Wire Size and Maximum Length

Do the condenser fan and indoor blower turn free without

rubbing, and are they tight on the shafts?

Has all work been done in accordance with applicable local

and national codes?

Are all covers and access panels in place to prevent air loss and

safety hazards?

Thermostat Heat Anticipator

Set the thermostat heat anticipators to equal the amperage draw

of the W1 thermostat circuit.

CAUTION

Before starting the system on the cooling cycle, turn the comfort

control to

OFF

and close the unit disconnect switch. This is

a precaution against foaming at startup which could damage

the compressor bearings.

Safety Hazard. Do not operate the unit without the evapora-

tor fan access panel or evaporator coil access panel in place.

Reinstall the access panels after performing maintenance

procedures on the fan. Operating the unit without the access

panels properly installed may result in severe personal injury

or death.

s

s

WARNING

NOTE: See the section on “Sequence of Operation” for a de-

scription of the cooling operating sequence.

To start the unit in the cooling mode, set the comfort control to

COOL

and to a setting below room temperature. The condenser fan motor,

compressor and evaporator fan motor will operate automatically.

Operating Pressure Checks

After the unit has operated in the cooling mode for a short period of

time, install pressure gauges on the gauge ports of the discharge

and suction line valves (behind the Compressor access panel).

Check the suction and discharge pressures and compare them to the

normal operating pressures provided in the unit’s

SERVICE FACTS.

NOTE: Do not use the PRESSURE CURVES from the unit's

SERVICE FACTS to determine the unit refrigerant charge. The

correct charge is shown on the unit nameplate. To charge the

system accurately, weigh in the charge according to the unit

nameplate and check subcooling against the Subcooling Charg-

ing Table in the SERVICE FACTS.

Voltage Check

With the compressor operating, check the line voltage at the unit

(contactor is located behind the Control access panel). The volt-

age should be within the range shown on the unit nameplate. If low

voltage is encountered, check the size and length of the supply line

from the main disconnect to the unit. The line may be undersized

for the length of the run.

Cooling Shut Down

Set the comfort control to

OFF

or to a setting above room temperature.

IMPORTANT:

De-energize the main power disconnect ONLY when

servicing the unit. Power may be required to keep the heat pump

compressor warm and to boil off refrigerant in the compressor.

WIRE SIZE

MAXIMUM LENGTH (Ft)

18

75

16

125

14

200

Summary of Contents for 4TCY4024

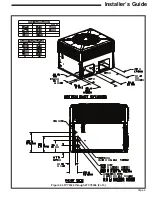

Page 5: ...Page 5 Installer s Guide Figure 2 4TCY4024 through 4TCY4036 2 of 3...

Page 6: ...Page 6 Installer s Guide Figure 3 4TCY4024 through 4TCY4036 3 of 3...

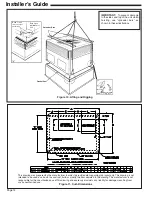

Page 8: ...Page 8 Installer s Guide Figure 5 4TCY4042 through 4TCY4060 2 of 3...

Page 9: ...Page 9 Installer s Guide Figure 6 4TCY4042 through 4TCY4060 3 of 3...

Page 18: ...Page 18 Installer s Guide Figure 20 Typical 4TCY4 Field Wiring Diagram...

Page 22: ...Page 22 Installer s Guide Notes...